The Plan Page

[ Home ] [ Previous Plan Pages ]

[ Special Things ] [ Earl Stahl Plans ]

gt-hunter1@home.com

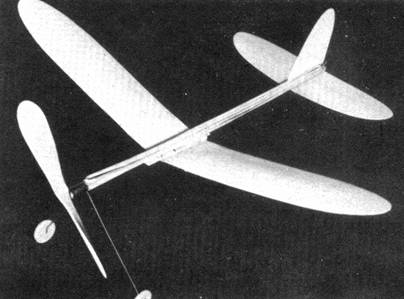

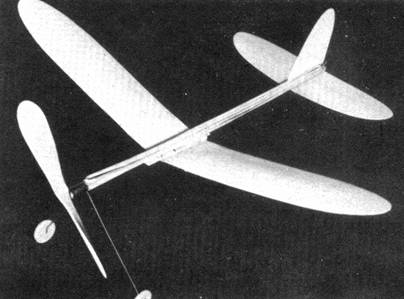

For forty years, Charlie Grant has experimented with fundamental rubber‑powered models like the Cloud Tramp. The proportions and areas in this photograph make for sport performance second to none.

CLOUD TRAMP

by CHARLES H. GRANT

This may be a

beginner's model but its performance commands respect.

Put one together and fly it whenever all the complicated stuff gets you down.All

balsa.

|

|

|

Why are you a model fan? Is it because you enjoy the frustration born of balky gas engines with only an occasional flight; because you enjoy the labor of building intricate structures; because you thrill to the tug of a motorized "yo-yo," roaring through repeated circles at the end of restraining control lines; or is it because you reap deep satisfaction from repeated, realistic, completely stable free flights requiring minimum construction effort and damage repair? If you prefer the latter, build this simple model. It will give you as many as 20 to 30 thrilling flights in an afternoon, without breakage, and all within the bounds of a baseball park.

Longer flights of a minute or more to altitudes of more than 300 ft. can be obtained by lubricating the motor with glycerine, stretching it 2-1/2 times its length and winding it to 900 turns. The motor should not be wound more than 400 turns when it is dry and wound by hand.

Study the plans carefully and before you start building be sure you know the exact function, material, size and shape of each part and how all parts are placed and held together in the assembly.

Start with balsa sheet: medium hard, 40 in. total length, 3 in. wide, 3/64 in. thick. From this, cut the wing, 22 in. long; the stabilizers, 10 in. long; and the fin, 3-3/4 in. high. Shape the wing tips, the stabilizer and fin outlines all according to the patterns given full scale in the plans.

From balsa sheet, medium hard, 4 in. long, 3 in. wide, 1/8 in. thick, cut wing incidence block and four ribs to the exact outline given in the plans. Then use:

Balsa: medium hard, 4 in. long, 3/4 in. wide, 3/16 in. thick. Cut wing center block from this to length and cross-section shown in plans. Sand the "V" bottom to precise shape.

Balsa sheet: hard, 2 x 2 x 1/16 in., from which cut two wing mount strips, 1-5/8 in. long and 3/4 in. wide, with grain running crosswise.

Balsa stick: hard balsa, 18 in. long, 1/4 in. square cross‑section.

Sawed balsa propeller: 8 in. long. Shave down blade faces, round tips, sandpaper all surfaces and "balance" on pin through shaft hole. Cut trailing edge at hub to concave shape shown in side assembly view.

Molded plastic propeller: 8 in. long. (This may be used if balsa propeller is not available but flights will be shorter because of greater weight and lower pitch of types now on market).

Wheels: hard wood, 1-1/4 in. dia., 1/4 in. thick.

Hanger-bearing for prop: steel, "L" shape, legs 13/16 and 5/16 in. long, cross-section half round 3/32 in. wide.

Washers: two, brass, 3/16 in. outside dia., 3/64 in. hole (min.), on propeller shaft between propeller and bearing.

Steel wire: hard (not annealed), 21 in. long, .032-.035 in. dia. From this make landing gear, prop shaft, tail hook, and motor hook according to size and shape given in plans, (Prop. shaft, tail and motor hooks are shown full scale).

Rubber for motor: 10 ft. long, 1/8 x 1/30 in. (Brown 1/8 in. flat is common designation).

Quick drying, waterproof model cement.

Miscellaneous implements, as pins, clothes pin spring clamps, sandpaper, pliers, knife, razor blade, etc.

To assemble, crease wing sheet at exact center and cement "V" center block in the crease. Hold in place until dry with pins and clamps as indicated, and support wing tips at dihedral angle shown until dry.

Cement four wing ribs to under surface of wing: hold with pins and clamps until dry.

Cement incidence block to wing "V" block rear edge.

Cement stabilizer and fin to motor stick: hold until dry with pins.

Cement prop hanger bearing to top of motor stick and bind firmly with thread.

Bind landing gear to underside of stick below bearing with thread, using plenty of cement to coat joint.

Put wheels on axles and bend up wire ends with pliers.

Cement tail hook to rear of motor sticks.

Pass end of prop shaft through prop, bend over end into loop and drive loop back into front face of hub after applying cement to loop.

Cement wing mount strips to motor stick at location shown.

Fasten wing in place on mount with 2-1/2 in. rubberband (use two if required).

Place washers on prop shaft and hook shaft into bearing.

Hook motor "S" hook over tail hook and string four strands of rubber through the prop shaft hook and the "S" hook, without tension. Tie ends of rubber together and locate knot at rear end of motor by adjusting the rubber loops.

The motor should include four strands of rubber, (two loops). One extra strand may be used with Sawed Balsa Prop when ROG take-offs and high climbing rates are desired.

Care in constructing, finishing and aliening your Cloud Tramp will give you the most reliable and best performing model plane you have ever built, Don't let its simplicity fool you.

To fly, balance plane on ends of two fingers, supporting plane at two points, each about 2 in. from and on opposite sides of the center wing chord from one another and just half way between leading and trailing edges.

If plane does not balance level, move the wing back and forth along the stick as required to bring plane in balance when supported on fingers.

When in balance, glide plane gently from hand launch.

When glide is smooth and even, wind motor by the propeller about 100 turns and hand launch gently. If plane flies without stalling or diving, wind about 300 turns and launch for a long flight.

If plane stalls, move wing back 1/4 in. If it dives, move wing forward 1/4 in. Then wind it again and fly, adjusting wing on stick until flight is even.

Maximum winds by hand are 400; with winder, 900.

Scanned From August 1954

Model Airplane News

[ Home

] [ Previous Plan Pages ] [ Special

Things ] [ Earl Stahl Plans ]