Model

builders will recognize the Stinson 0‑49 as an excellent subject for a flying

scale contest model. In appearance it is attractive yet not difficult to

build. Best of all, the aerodynamic proportions are near perfect; our test

model was built to scale and it was unnecessary to even increase the wing's

dihedral or enlarge the proportions of the tail surfaces to obtain long,

stable flights. The relatively long fuselage permits use of a powerful motor

of considerable length, thus increasing the length of power flights. To make

possible use of a propeller of sufficient size the landing gear is

shown in the extended or flight position. In addition to its excellent flight

qualities, the Stinson offers a wealth of detail to be reproduced in the

radial motor, cabin windows, etc., for those who seek maximum "scale" points

in flying scale contests.

Fuselage

The

fuselage underframe is constructed first; it is shown lightly shaded on the

plan. Work directly over the plan and make two side frames; longerons and

uprights are 3/32” square balsa. While the curvature of the lower longerons is

not excessive, it is advisable to steam them to shape so they will not have a

tendency to draw the upper longerons out of alignment when removed from their

jig. When dry, the side frames are joined by 3/32" square cross‑pieces. Check

frequently to assure proper alignment of the entire structure.

With

exception of the cabin formers, the fuselage formers are cut from soft grade

1/16" sheet balsa. It will be noticed that some of the formers lack notches

for the stringers, and where this is the case the stringers are attached

directly to the sides, as shown. Cement formers to their respective positions

and then add the 1/16" square stringers. The stringers that extend along the

sides are cemented directly to the underframe.

Because of

the cabin's unusual shape, special care must be exercised to insure accuracy

and strength. Full size cabin formers are shown and they are made from hard

grade 1/16" sheet. Assemble the parts of formers C‑1 and C‑4 directly over the

plan ‑ they must be exact. Looking at the side view of the fuselage, it will

be noticed that C‑1 is attached at an angle to the top longeron. Cut a

cardboard pattern to exact angle, to aid in accurately attaching the front

member to place. Cement C‑1 and C‑4 to place and then cut two ribs to shape

indicated on the side view; assemble them to the notches in the formers. If

you have reproduced the structure with greatest care, the ribs will have the

correct incidence 2‑1/2 degrees positive. Attach the other formers and the

3/32" square pieces that form the cabin. Thoroughly recement all joints.

To

effectively represent the metal nose of the real ship, the front from section

No. 1 to No. 2 is covered with soft 1/32" sheet. Two 1/8" sheet balsa discs

are cemented to the front of section No. 1 and then shaped as indicated. The

engine cowling is made in a similar manner. A frame consisting of two circular

bulkheads and four 1/16" square spacers is assembled as indicated by the

broken lines; this structure is covered with 1/32" sheet. The rounded nose

section is made from laminations of 1/8" sheet, the centers of these discs

being removed to the extent indicated by broken lines. Details of the nose

plug are indicated. The removable section is made to fit accurately to the

crank case which is cemented within the cowl front. Finish the nose and cowl

by sanding to finished shape but do not cement the cowl to the nose until

later.

Landing Gear

Before

constructing the landing gear full size sketches of the various wire parts are

made; these parts are bent from .034 music wire. With needle and thread sew

the top member of the front unit to the fuselage longerons and cross‑member.

Since the nose is covered with sheet balsa, long nose pliers will probably

prove helpful for working the needle about the wire and through the formers.

The other two wire units can be temporarily held to place until the parts are

accurately fitted and the whole structure properly aligned. Neatly but firmly

solder the struts together. Securely bind the rear struts to the lower

fuselage stringer, then reinforce the area with 1/16" sheet, as shown. The

center strut is not attached to the fuselage, it being left free to twist and

spring and thus absorb shock. The balsa and rubber tubing fairings are not

attached to the landing gear until later.

Wheels are

made from laminated balsa discs or they may be purchased. Bearings should be

cemented to the sides so they will revolve smoothly and accurately.

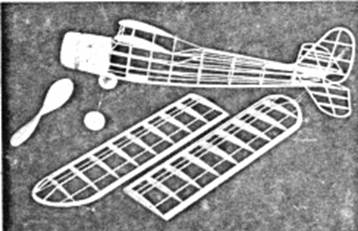

Wing

Because of

limited space a full size wing plan could not be reproduced, so a full scale

layout should be made on a large sheet of paper and work done directly over

it. Taper and sand the trailing edges before pinning them into position over

the plan. Ribs are cut from light grade 1/20" or 1/16" sheet; sixteen regular

and two tip ribs are required. Pin ribs to position and then attach the

leading edges and spars. Assemble tip pieces, which are cut from 1/8" sheet,

and cement them to place. Once the leading edges and tips are trimmed and

sanded to shape the wing frames are completed.

Tail Surfaces

Construction of the tail surfaces is quite simple. Both rudder and stabilizer

are made similarly, the plans being nearly self‑explanatory. Make the

stabilizer in one piece. The streamline rib shape is made by gluing 1/16"

square strips of a soft variety to both sides of the underframe and later

cutting them to shape. This manner of construction is strong yet light.

Carefully trim and sand the parts so a smooth covering job can be made.

Propeller

Carve the

propeller from a very hard balsa block 8" x 1‑1/2" x 1"; lay out the blank as

shown. Always cut the back face of the blades first. The hardness of the wood

will determine the thickness of the blades, its shape can be seen on the

photos. Thoroughly sand the propeller and then apply several coats of clear

dope with light sanding between each coat to produce a nice smooth finish.

Equip the prop with some kind of free‑wheel device so the glide will be

improved.

The

propeller shaft is bent from .040 music wire. Place several washers between

the prop and nose plug and bend a loop on the front of the shaft into which a

mechanical winder can be hooked.

Covering and Assembly

Before

starting to cover your Stinson the entire frame should be lightly but

thoroughly sanded to remove all roughness. The several flat windows between

sections C‑1 and C‑4 are covered with cellophane at this time --other windows

are celluloid and not added till later. Being an Army plane, standard blue and

yellow colors are used. Use banana oil for adhesive and cover the fuselage

with blue tissue; to prevent wrinkles numerous small pieces of tissue should

be used. The sheet‑balsa‑covered nose and cowl are tissue covered, too. Wings

and tail surfaces are covered with yellow tissue; grain runs spanwise. Tips,

etc., require separate pieces. The parts are lightly sprayed with water to

tighten the tissue but are not doped until the ship has been assembled.

To

assemble your 0‑49 follow this procedure: Finish the cabin windows first. Use

the very lightest celluloid available -- film negatives boiled in water to

remove the emulsion are excellent. Start at the back and make accurate paper

patterns of each section, cut the celluloid to shape and cement to place,

being careful to avoid cement smears. Pattern for the front windshield is

given but it may need slight altering to exactly fit your model. Thin strips

of tissue doped to the windows, as pictured, will improve its appearance.

Finish the

landing gear by cutting the balsa covers from 1/8" x 1/2" soft balsa; these

members are streamline in cross section. Cut 1/16" deep grooves in the struts

to hide the wires and cement the wires fast; do not, however, attach the tops

of the struts to the fuselage. Cover the struts with several layers of colored

tissue. Split the rubber tubing, slip on the rear struts and then recement.

Wheels are colored and held to place by washers soldered to the axles. It will

be necessary to temporarily cut the tail post to admit the stabilizer, which

is attached by cement at the angle shown. The rudder is off set 1/16" so the

model will glide in right circles. The wings are fitted to the fuselage with

tips elevated 1‑1/2" ‑‑ scale dihedral. The "vee" wing struts are shown half

size on the plans; they are 3/32" x 3/16" balsa cut streamline. Struts join

the wings at the "X". If the builder wishes to add engine details within the

cowling it is best done before the unit is cemented to the nose. Now that the

model is assembled, a coat of clear dope is applied to all the covered

surfaces.

Minor

details are usually the features that make the model really attractive. The

0‑49, an Army ship, of course should have the regular wing stars and rudder

stripes. These can be made from colored tissue as can the "U. S. ARMY" on the

wing's under‑surface. Control surface outlines, flaps and slots, etc., are

represented by thin strips of black tissue. As noted before, engine details

within the cowling will go a long way in adding to the ship's attractiveness.

Naturally the propeller and other exposed wood parts are color doped.

About ten

strands of 1/8" brown rubber are required to power this model. Measure the

strands to the correct length and attach them to the prop shaft loop. Drop the

rubber into the fuselage and slip the bamboo pin into place to attach the

rubber in the rear. Your model of the Stinson 0‑49 is now ready for its first

flights.

Flying

Select a

calm day and a grassy field for the test flights. However, before taking the

ship to the flying field, it should be made to balance by adding weight to the

nose or tail, until it rests on an even keel when held at the center of the

wing's chord. Test glide the plane and readjust the weight, as necessary, to

obtain a nice smooth glide. Once the glide is satisfactory, try short power

flights and if any corrections are required, make them by offsetting the

thrust line. A sliver of wood at the top of the nose plug tilting the thrust

line down at a slight angle will probably "iron out" a stall, while right or

left thrust will adjust the circle during the power flight. While under power,

circles should be large and to the left; in the glide it should turn to the

right. A little effort and caution will reward you with a fine plane which is

truly attractive yet a remarkable flyer.