|

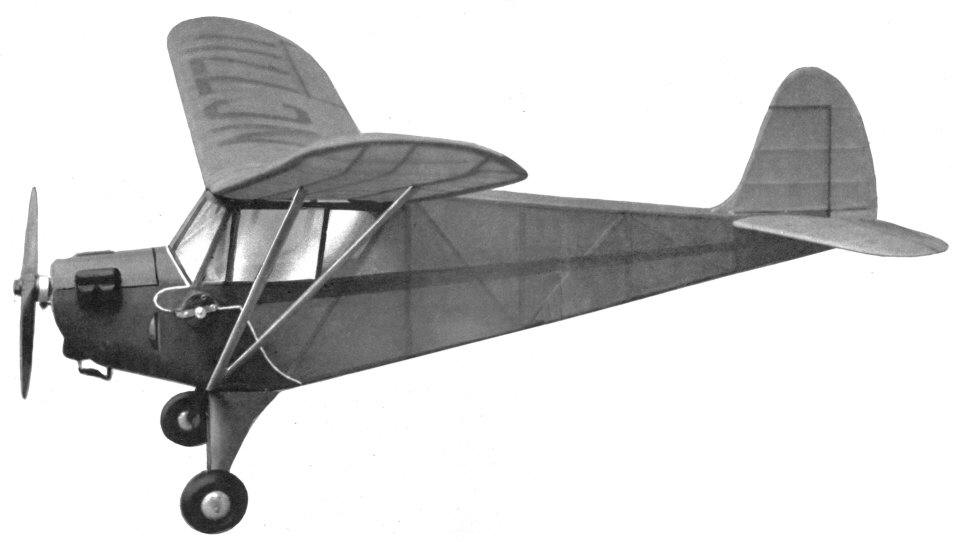

Aeronca Tandem BY RONNIE ALBERT

Make your next contest ship look like a real airplane!

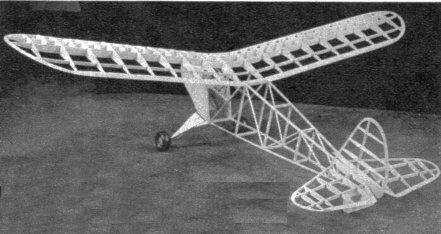

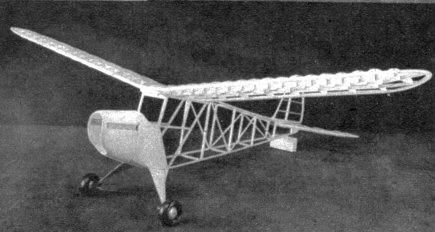

AND now its scale gas models! Yes, sir, fellows, building and flying gas jobs the exact replica of the prototype is rapidly becoming one of the most popular phases of modeling. The fact is -- and you can't deny it -- that scale gas models were never given a chance to show their true worth. The "experts" of years back decided, after building one or two scale models, the prototype of which wasn't of ideal aerodynamic design, that "scale models won't fly" -- and then did a good job of selling the rest of us modelers on this conclusion. (That's how a lot of these things start, you know.) To be frank, we were one of the lads thus influenced until recently, when we wanted proof of the flying efficiency of scale gas models. We noticed the fine aerodynamic proportions of the popular sport light planes, and with this as inspiration developed the model appearing on these pages -- the Aeronca Tandem. And after watching it perform, climb into the sky and then settle for a beautiful flat glide -- just like any present-day contest job -- we say that if you want to build a gas model of contest caliber and still have a model that looks like an airplane, this Aeronca Tandem is it. Before describing the actual construction, here's a hit of information as to the general specifications. With a wing area of 286 square inches and a total weight, with the Ohlsson 23, of only 20 ounces, the wing loading for this Class B craft is 10 ounces per square foot. Because of the straight wing and rectangular fuselage, construction is extremely simple. CONSTRUCTION Lay off both sides of the fuselage directly on the plan, using 3/16" square hard balsa for longerons and uprights, and then, after the cement is dry, with the aid of the top-view outline, cement the cross braces in place, thereby forming the fuselage. Next, cut from 1/8" birch plywood the front bulkhead A-A and cement in place against the front upright. Add the motor bearers, which are of 1/4 x 3/4" spruce stock and reinforce the joint with plenty of cement. (Testers please take note.) Since the majority of Class B engines have the same distance between lug centers, the measurements of the pivot mounts should be as indicated. However, in case your engine does not fit the mounts shown, the thickness of the pivot mount should be altered accordingly. After the pivot mounts are securely and accurately in place, our next job is shaping the nose. This is done by spot-cementing rectangular blocks of soft balsa directly to the front bulkhead and, after the cement has dried, carving the balsa until the desired shape results. Once the nose shape is completed, the balsa is cut loose from the bulkhead and hollowed out so an average wall thickness of 1/8" remains. Apply a few coats of thick clear dope to the inside surface and then cement the unit permanently in place against the front bulkhead. To make way for engine installation and trouble shooting, the top of the nose is removable and held in place for flying with rubber bands. Next install the coil and wires, and then cover the indicated section of the nose with 1/16" sheet balsa. All joints are then sanded smooth and given a few coats of thin clear dope, shading between coats with No. 00 sandpaper. The landing gear, always an important part of any model, is built up from 1/16" diameter steel wire and soldered at all joints. To give the effect of a single strut, the interior of the 1/16" wire outline is filled in with 1/8" flexible sheet balsa. The landing gear, because of its solid nature, is so attached to the fuselage that it pivots backward when contacting a stubborn obstacle. (A rock to you, pal.) To accomplish this, the rear of the gear is mounted in a section of 3/32" O. D. brass tubing, which in turn is anchored securely to the fuselage cross brace. The front of the gear is held in place with rubber bands, the tension of which is regulated via the trial-and-error method. Thus the excess shock which cannot be absorbed by the M & M airwheels is taken care of by the rubber bands. The position of the battery case is always of great importance on any gas model, the general idea being to locate the batteries as close to the center of gravity as possible, low in our case, easily accessible, and adjustable, so the model may be balanced by shifting the unit. Ours are the penlite batteries with the commercial case, mounted directly on the trapdoor as shown. The door is of solid hard balsa, 3/16" thick, and has a cloth hinge, one end of which is cemented to the fuselage and the other to the forward end of the door. The door is held in position with rubber bands, but should these slip off, little harm can be done, because the wind resistance will tend to hold the door close to the fuselage. In making the stabilizer, first cut from the standard rib material (1/16" stiff sheet balsa) all ribs, and cement them in place along the 1/8" sheetbalsa spars, which are tapered to fit the ribs. After the cement has dried to permit handling, the leading edge is cut from 3/16" sheet balsa and cemented in place. Then the trailing edge is cut from 1/8" sheet balsa and added after the leading-edge cement is sufficiently dry. Both stabilizer halves are then compared for similarity and put aside until the covering stage is reached. The rudder is made in exactly the same fashion as the stabilizer. The wing of our Aeronca is of orthodox construction and, like the rest of the model, very simple, yet extremely strong. First cut the three spars from 1/8" hard sheet balsa, the front and middle spars being 3/4" deep, the rear spar measuring 5/16". After the spars are cut to the desired length, the ribs are cut from 1/16" stiff sheet balsa and cemented in place directly over the drawing. The left-wing panel, as in the case of the stabilizer half, is not shown, but the outline is obtained by reversing the outline shown. After the ribs are in place, the leading edge, which is cut from 1/4" sheet, is cemented in place and allowed to dry. Then the 3/16 x 5/8" trailing edge is notched to fit the ribs and cemented in place. Both tips are built up from 3/16" sheet and carefully sandpapered smooth. Upon completion of both left and right wing panels, join them together at the center as shown, forming the required 4-1/2" dihedral on each tip. To reinforce the dihedral joint, layers of 1/8" hard balsa are cemented to both sides of all three spars. The upper camber of the two center ribs is cut down 1/16" and the center section covered with 1/16" flexible-sheet balsa. The wing is then set in place on top the fuselage and a solid block of medium balsa cemented directly over the sheet covering. Then the block is cut down to fit in with the contour of the fuselage, and the window section cut out and covered with thin celluloid. The wing struts are cut from 3/16 x 3/8" hard strips to fit after the dihedral is in place. The struts are removable and are held in place, sections of 1/16" wire protruding from the wing at the front and rear spar positions of rib X. The sections of wire telescope into 3/32" O. D. aluminum tubing cemented into the spar ends. To remove the struts, merely slide out. The entire model is covered with Silkspan GM paper, your favorite color (if you can still get it) , and doped three times with thin, clear dope. The stabilizer halves are then cemented in place on the fuselage sides, care being taken so the zero-degrees incidence is duplicated. Next the rudder is cemented in place and the wing held in position with rubber bands. The correct angle of incidence is built into the fuselage, so you need not make any provisions for more incidence. The model is balanced at a point one third from the leading edge by shifting the batteries; to test the balancing point, glide the model a few times. When gliding, adjust the rudder so the tendency to turn is clockwise, and for flying, make certain the job climbs with the torque. The first test flight should be at half throttle, but after that -- well, we know darn well you'll really rev up your hot (?) iron and watch your Aeronca tear upward just like your best contest job! But hold it, brother! You don't want to run cross country every time your job takes the air, so why not adapt it for "guide-line" flying. Kill two birds with one Aeronca by adding the guide-line mechanism and, if you're still puffing from that last free flight, snap the wire control lines in place and pilot your job just as you wish. For those of you who are not yet familiar with this popular method of flying gas models, we shall briefly outline the working principle. The actual working mechanism which makes it possible to control the flight of a guide-line model consists of hinged elevators, the movement of which is controlled by two wires. The wires are attached to a simple mechanism located at the model's center of gravity. Pulling one wire causes the elevators to move downward and make the model dive. Tension on the second wire causes the elevators to move upward and, if the angle is sufficiently great, the model will eventually loop. The end of each wire line is attached to a handle held by the "pilot," and by twisting the wrist slightly, various maneuvers are easily accomplished. But now let us get down to the actual conversion to put our model in the guide-line class. GUIDE-LINE CONVERSION You will note that the plans for the model do not contain any definite structural changes required for guide-line conversion, but merely dotted lines to indicate the elevator and rudder-tab area, position for controlline cable centers, and rib location for the control-line spreader. With the aid of the special control-line flying mechanism, one can quickly visualize the structural changes required for this type of flying. Our first task in conversion is making the movable elevators. Merely cut off the ribs along the stabilizer half plan and fill in the area with 3/16" medium sheet balsa. Streamline the elevators to fit in with the rib contour and proceed to cement the elevator hinges in place. To act as a hinge bearing, cement pieces of 1/32, sheet aluminum to stabilizer ribs 2 and 4 of the shape shown. After these are in place, bend the "axles" from .035 piano wire and sink into the elevator edge, using a thick layer of cement to insure permanency. Now let us get to the actual construction of the control mechanism. Before doing this, however, we shall again give the newcomer in this field the fundamental principle on the control-mechanism nucleus, the working theory of the control plate. The mechanism inclosed within the fuselage of the model to convert the tension of the two control lines into up-and-down elevator movements is merely a combination of two levers. By pulling the front wire, the control plate is moved, causing the elevator-control rod to move backward, thereby moving the elevators up. Tension on the rear line causes the elevator-control rod to move forward, moving the elevators down. Changes of tension on the control lines will naturally result in different elevator movements and, as pointed out previously, will cause the model to climb, dive, loop or whatever the case may be. The control mechanism for our Aeronca is built up on a section of hard 3/16" sheet balsa and cemented in place after the unit is completed, so the two 1/32" bronze control cables protrude from the fuselage at the points indicated by the center lines. First cut the control plate from 1/16" sheet aluminum and drill the necessary holes for the control cables, pivot point, rubber bands which constitute the automatic pilot, and the .035 hole for the elevator-control rod hook. The holes for the control cables are 1/16" in diameter, while the holes for the rubber bands are slightly larger; 3/32" will do. Bolt the control plate to the 3/16" hard balsa base, spacing a washer between the control plate and the balsa surface to minimize the amount of friction. Then attach the control cables to their respective positions and check the entire unit for free movement. The rubber bands which make up the automatic pilot are added next, and for the benefit of those who are not familiar with the duties of these seemingly unimportant rubber bands, we will explain. When the wind suddenly gets under the wing of the model and forces the control lines to slacken, control over the model is momentarily lost because we can no longer transmit our desired movement to the elevators. To prevent the model from getting out of control when the control lines slacken, rubber bands are attached to the ends of the control plate and, since the tension of these rubber bands is equal, the control plate is pulled back to the neutral position when the control lines slacken. The model is therefore kept on an even keel until the operator again has the lines taut. Now that we are aware of the great role the rubber bands on the control plate play, let us finish our mechanism by attaching the elevator-control rod in place. With the control plate and the elevators both in neutral position, attach one end of the elevator-control rod to the elevator horn, as shown, and the other end to the control-plate arm, using the elevator-control rod hook as indicated in the sketch. When adjusting the elevators for flight maneuvers, pins are inserted in the control-plate base to limit the movement, which in turn will regulate the setting of the elevators. For average flight maneuvers, the elevators move upward 1/8" and downward 3/32", while for stunt flying the upward movement is 3/16" and the downward measure 1/8". The elevators are adjusted by setting the pins in place via the trial-and-error method. Since the success of any control-line model depends upon keeping the lines taut at all times, the model must always "fly against the circle" -- tend to turn to the right when flying in a counterclockwise circle. To accomplish this, the rudder tab, which is built into the rudder in much the same fashion as the elevators were constructed (with the exception that the hinge of the tab is .035 sheet aluminum) is set about 3/8 inches to the right, and the engine thrust line slanted two degrees to the right. This will insure that very important right-turning tendency. To prevent the model from side-slipping to the right from too much rudder and engine adjustment, a control-line spreader, the measurements of which are given on the sketch, is cemented to the left wing panel along rib A. Thus the control cables pass from the control plate through the fuselage side bushings and then on through the control-line spreader eyelets and finally, at a point eight inches out from the spreader, are attached to the piano wire control cables. The control lines, as you will note, are .012 piano wire, each fifty-one feet in length. Thus, the total distance from the control handle to the center line of the fuselage is exactly fifty-two feet six inches. (That gives you speed demons sixteen laps to the mile.) Nothing much need be said about the control handle except that the control lines should be attached securely in place. The handle is carved from white pine to fit your hand. Since two fifty-one-foot lengths of springy piano wire can get you into an awful tangle, it is best to keep the lines on a special spool at all times when not in use. Of course, any type spool may be used, but the simplest and most efficient is an eight-inchdiameter plywood disk with quarter-inch dowels inserted every two inches along the outside edge. As for flying this type model, the greatest danger comes from letting the control line slacken -- which means the model should be launched with the wind, never looped with the wind at your face and, of course, never flown in a high wind unless you have a very powerful engine. This Aeronca is ideal as a guideline trainer because of the high wing and slow speed, and may be used as a Class C model in case you're that ambitious. After flying this model both as a free-flying and guide-line type, we believe you'll definitely agree that scale gas models are finally coming into their own! Scanned From February, 1942 |

||||