|

1939

STOUT TROPHY

WINNER

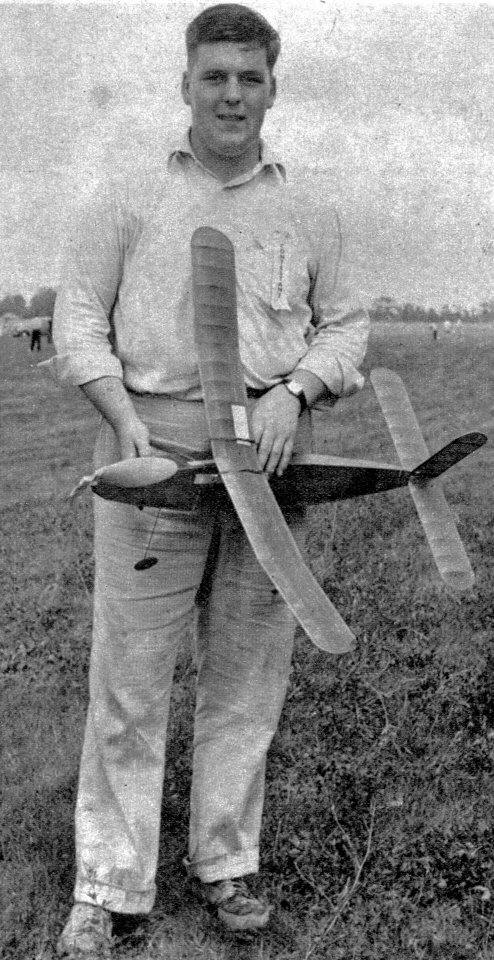

This model's 36-minute flight won the Stout Trophy and

qualified the builder as captain of the American Moffett team.

Bob Toft. Has won a second in gas, first in rubber at Nationals.

BY BOB TOFT

THIS is a typical American model. It was finished at

five o'clock in the morning, a few hours before it won first place in the

Minneapolis Model Aero Club's eliminations for the Nationals. It won for

the builder an all-expense air-lines trip to Detroit, where he gained the

Stout Trophy. The 12-3/4-minute average of three flights that the model

hung up was one of the outstanding marks of the contest. The model is

extremely simple, and the inclusion of full-size parts in the plans should

make every beginner reach instinctively for his favorite razor.

CONSTRUCTION

Fuselage. A plan view of the fuselage should be

drawn up. All measurements are given on the plans, but any not supplied

may be had by multiplying the size of the part on the plan by four, the

plans being one-quarter full size. Two sides of the fuselage should be

built simultaneously to insure duplicate shapes, and after the cement has

dried they should be removed from the drawing and checked. If one or both

of the fuselage sides has warped out of line, insert one or two diagonals

in the proper places to straighten it out. The two fuselage sides should

be connected at the extreme rear and the cross braces added. If rubber

bands are stretched around the fuselage after two opposite braces have

been added, the next two may be cemented in without waiting for the last

set to dry. The landing gear is bent to shape and embedded between the

full-size gussets given on the drawing. After the nose and tail ends of

the fuselage have been filled in with 1/16" sheet balsa, the corners of

the longerons are sanded slightly round and the fuselage covered with

tissue.

Wings. After nineteen ribs have been cut from 1/16"

balsa, bamboo wing tips are bent to the outline shown on the full-size

plate. After assembling the entire wing, the bottom spar, leading, and

trailing edges should be cracked slightly for dihedral. The top spar and

sheet covering will have to be cut out a little to provide the necessary

gap to be taken up by the wing when the tips are raised. When covering,

make sure that the wing does not warp. If the shrinking of the tissue

after it has dried causes a warp, it can be removed by holding the wing in

the proper position while doping.

Tail. The stabilizer is made in much the same

manner as the wing, and it also should be free from warps. After it has

been assembled and covered, cement it to the tail plug at the proper

angle, a small incidence block being cemented under the leading edge. The

incidence block should be slightly more than 1/8" thick. The rudder is

flat, having been built up from 1/8" square and 1/8 x 3/8". When cementing

the rudder to the top of the stabilizer, offset it slightly, as the model

is intended to fly in large circles.

The wing mount and nose plugs are illustrated in

detail. Be sure to brace the tail plug securely, and the cross pieces it

is cemented to should form a T section.

Propeller is carved from a medium-hard 2 x 2 x

9-3/4" block and should be doped and then sanded with successively finer

grades of sandpaper. After the hinge parts have been carefully cut and

bent to shape, they are cemented to the prop in the proper position and

bound with thread. Three or four coats of cement should follow on the

bound portion to insure long use with little fraying or wear. The

counterweight should be oversize, so that it may be trimmed down to

balance. In cutting the prop at the point at which it folds, a very fine

jig or scroll saw will not rip the wood excessively. In positioning the

prop for folding, the nose plug should be inserted so that the stop is in

such a position that the prop folds flat against the left upper fuselage

side (looking from the rear).

The motor used in the original was composed of twenty

strands of 3/16" rubber, 50" long. A good grade of lubricant should be

used, and it is necessary to employ rubber tubing on the prop hook and

rear hook.

FLIGHT

The original model was adjusted by setting the wing and

tail at a definite angle to each other -- two degrees angular difference

-- and maintaining that relation during all adjusting. The wing was

shifted to produce the best glide possible. The center of gravity was

about an inch behind the trailing edge of the wing when the best glide was

had. The wings were perfectly straight with no warps for adjustment. The

rudder was warped slightly for a right turn. The nose plug was offset to

produce the correct climb adjustment. The model did not climb very fast,

but a long motor run gave it more time to strike a thermal. Even without

the help of thermals, the glide stretched out the time pretty well. The

model circles to the right under power and in the glide. The circles are

about one hundred feet in diameter, because the designer thinks that too

tight a circle will induce an unnecessarily steep glide. The maximum turns

are twelve hundred, a few of which remain after the prop has folded.

BILL OF MATERIALS

|

Fuselage |

| 5 pcs. |

1/8 sq. x 36" |

longerons |

| 8 pcs. |

1/8 sq.. x 36" |

cross braces |

| 1 pc. |

1/16 x 3/16 x 11" |

bamboo wing runners |

| 1 pc. |

1/16 x 3/4 x 12" |

wing mount |

| 1 pc. |

.045 x 36" wire |

wing mount |

| 2 pcs. |

1-3/4 sq. x 1/4" hard balsa |

nose plug |

| 1 pc. |

1-1/4 sq. x 1/4" hard balsa |

nose plug |

| 4 pcs. |

2 x 2 x 1/16" |

wheels |

| 1 pc. |

1/16" hole x 1" brass tubing long |

wheel hub |

| 1 pc. |

2 x 1/16 x 16" |

balsa fill-in |

| |

|

Wing |

| 3 pcs. |

1/8 sq. x 36" |

leading edge and spars |

| 1 pc. |

1/8 x 3/8 x 36" |

trailing edge |

| 1 pc. |

1/16 x 2 x 36" balsa |

ribs |

| 2 pcs. |

1/16 sq. x 12" bamboo |

wing tip strips |

| 1 pc. |

1/20 x 3 x 36" balsa |

leading-edge covering |

| |

|

Stabilizer |

| 1 pc. |

1/16 x 2 x 12" |

ribs |

| 2 pcs. |

3/32 sq. x 36" |

spars |

| 1 pc. |

1/20 x 3 x 36" |

leading-edge covering |

| 1 pc. |

1/8 x 5/16 x 36" |

trailing edge |

| 2 pcs. |

1/16 sq. x 12" |

bamboo stab tips |

| |

|

Rudder |

| 1 pc. |

1/8 sq. x 36" |

rudder ribs |

| 1 pc. |

1/8 x 1 x 36" |

leading edge, trailing edge, rudder base

rib |

| 1 pc. |

1/16 sq. x 12" |

bamboo rudder tip |

| |

|

Miscellaneous |

| 1 pc. |

1/16 diam. x 36" |

landing-gear, prop shaft |

| 1 pc. |

1/32 x 3/8 x 2" |

brass prop hinge |

| 1 pc. |

2 x 2 x 9-3/4" |

prop block |

| 1 pc. |

rubber or cambric tubing |

for shaft |

| 4 pcs. |

1/4" diameter |

copper washers |

| 4 sheets |

|

colored tissue paper |

|

Solder for prop counterbalance, Cement, dope,

thread, plastic wood |

Scanned From December 1939

Air Trails

|