|

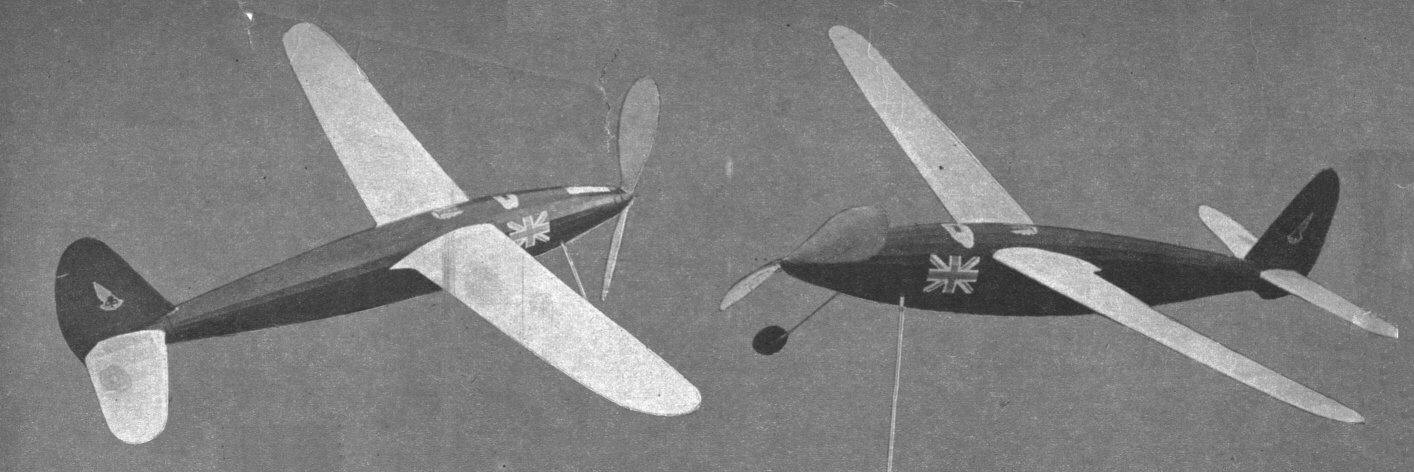

An ultra streamliner that set an international mark of

33:09 to win

the King Peter Cup.

BY ROBERT COPLAND

DRAWINGS BY PAUL PLECAN

A one-quarter-scale side view. |

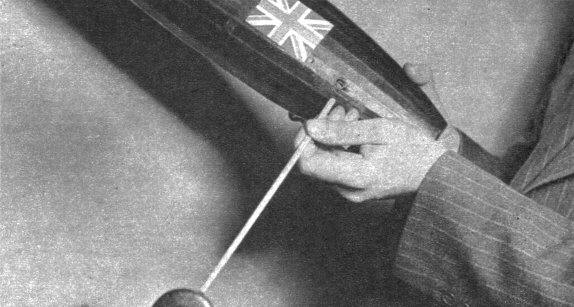

Butt ends of wing spars fit into sheet balsa boxes in the fuselage. |

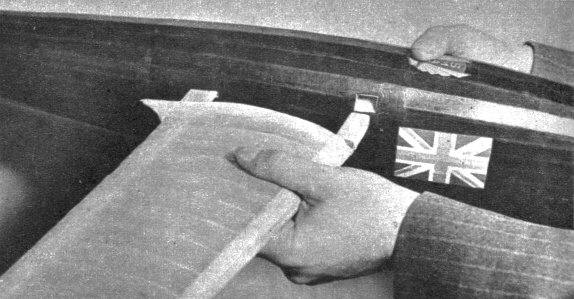

Stabilizer fits info last bulkhead; held down by detachable rudder. |

Detachable rudder fits into tubular stern post. |

|

From spinner to tail fuselage is one unbroken

streamline. Wings are carefully faired into fuselage. |

|

Robert Copland has been hot on the trail of the

Wakefield Trophy for the past five years. He's come close but has

never finished in No. 1 position. In view of his record in other

contests it seems remarkable, that he hasn't won it. He placed third

at the 1936 Wakefield in Detroit. While in America that year he flew

in our national contest and placed a good second in the Stout Outdoor

Fuselage with 20:07. Back home in England that same year he won the

1936 British Cup Competition. The Pilcher and the Weston Cups were

gathered into the Copland collection during the 1937 English campaign.

In 1938 he set an international record for rubber-powered cabin

fuselage with 33:09 at the King Peter Cup Competition in Yugoslavia.

(This record stood until Korda's 1939 Wakefield flight.) Last summer

he was fourth in the 1939 Wakefield finals at Bendix, New Jersey.

His outstanding work has been done with

rubber-powered fuselage jobs. But he's also one of England's best

indoor builders. His flights of over 18 minutes for hand-launched

stick models are listed on the official English records.

Americans have come to regard Copland as a

permanent member of the English Wakefield team. He was a member in

1936 and 1939 -- the two times the English have visited us for the

finals. He takes his contest flying seriously and works about the

hardest of any contestant we've seen. When his model got off on a long

flight at the last Wakefield contest, he didn't wait for help but dug

in and did the roadwork himself in mighty fast fashion -- which is the

acid test of one's model enthusiasm. Watching him in action gives the

impression that sooner or later the Wakefield Trophy will some day

bear his name.

The British Champ is the design that set the 33:09

international record mentioned previously, and that took fourth in the

1939 Wakefield. This ship was favored to win the Wakefield and had

averaged well over, four minutes on all of its test flights, made the

night before. That it did not place higher was due principally to the

extreme heat conditions with which foreign contenders had no previous

experience.

Having seen this job perform at Bendix, we wonder

just what it would do with an American high-powered rubber motor. (Due

to scarcity of thermals at English contests, the boys over there find

low-powered, long-running motors to be best.) -- Gordon S. Light. |

CONSTRUCTION

THE wing has to be constructed first, as it is used to

place the wing mount channels in position. All the wing ribs are given

full size, and both sets should be cemented to a sheet of stiff bristol

board. After two of the # 1 ribs have been cut from 1/16" sheet, the

template should be trimmed down with scissors or a razor to the next

smaller size. Two ribs of each size (#2 to #21) are needed, and all should

be cut from 1/20" medium balsa sheet. The wing tip is given full size, and

should be cut from medium-hard 1/8" sheet. The leading and trailing edges

should both be tapered to the sizes indicated on the plans, and it is a

good idea to trim the trailing edge to the approximate finished cross

section, as it is harder to trim it once it has been cemented in place. In

assembling the wing panels, the leading edge should be raised off the work

bench by inserting scrap bits of 1/32" sheet balsa at regular intervals

along the length of the leading edge.

The trailing edge should be propped up with 1/16" scrap

balsa placed under the front portion to keep it at an angle to the work

bench while the ribs are being cemented in place. After all the ribs have

been cemented in place, the wing panels should be left aside to let the

cement dry completely, as the wings might warp if they are removed from

the workbench before the cement has had a chance to dry. The trimming of

the butt ends of the leading and trailing edges is shown on the plans, and

should be done with accuracy and care. Both the leading and trailing edges

are trimmed on the bottom to obtain 4" dihedral when the wing rests flat

on the bench on the portions that have been trimmed. Two channels, 4"

long, are now made of hard 1/16" sheet. The inside dimensions of the

leading edge channel are 9/16 x 5/8"; trailing edge channel, 3/l6 x 7/8".

Both channels should be wrapped with silk or bamboo paper, with an extra

coat of cement applied over it. When trimming the butt ends of the wing,

make sure that the wings fit snugly into the channels.

Fuselage. Draw a center line on a strip of paper

36" long, or directly on the workbench. Mark off the correct spacing

between the bulkheads, and draw in the widths, which can be taken directly

from the full-size bulkhead outlines. Cut the correct amount of each

bulkhead (four in most cases) and cement two of each size together. Use

hard 1/16" balsa for the bulkheads as they are narrow and would be

slightly on the weak side if light balsa were used. Cut out only two #9

bulkheads of the narrow type, as the upper portion of #9 is different from

the rest of the bulkheads. Each bulkhead is made up of upper and lower

portions, each portion 1/8" thick, due to the fact that it is laminated

from two 1/16" thick bulkheads. Since only the bottom half of the fuselage

is built first, do not cement the entire bulkheads together. Pin all of

the bulkheads in place, propping each one up with scrap 1/20" sheet. The

proper steps in constructing the fuselage are shown under the side view of

the fuselage. The top and side longerons are the first ones to be cemented

in place, followed by a longeron between each side and top longeron.

Remember that all longerons are cemented over all bulkheads except #1 and

#16. On #1 and #16, the longerons are butt-cemented against the bulkheads,

the outside edge of each longeron being flush with the outside edge of the

bulkheads.

In Step 2, the remaining longerons are cemented in

place, two between the longerons already in place. Complete the tail end

of the fuselage behind #16, and let the cement dry thoroughly before

removing the lower half of the fuselage from the workbench. After removing

the lower half from the bench, turn it upright and proceed to add the

upper halves of each bulkhead. A typical bulkhead should now appear the

same as Step 3. The longerons on the upper half of the fuselage are spaced

the same way as those on the bottom, so repeat the procedure used in

spacing the lower longerons. The nose and tail ends should now be filled

in with scrap 3/32" balsa to provide surfaces to be gripped when the motor

is being wound. The rear wing channel should be cemented in place in the

space allowed in the cut-outs on pieces "T" that are cemented to the rear

of bulkhead #9.

After the cement has dried, slide one of the wing

panels on. Insert the front channel over the wing leading edge, and then

insert the other wing panel into place in both channels. The bottom of the

front channel should be 1-3/16" above the fuselage center line, and if it

is, fill-in pieces should be cemented around it on both sides of the

fuselage. If the front channel is too high, remove both wing panels, and

correct the position of the "T" pieces by cutting them away and

recementing them in place again, at an angle more parallel to the thrust

line. Fill in the areas around the channels, trim the channels off near

the fuselage, and sandpaper them flush with the fill-in portion. The

landing gear struts are made of bamboo, and are of streamlined cross

section, to keep them from revolving in the paper tubes into which they

slide. Four layers of brown wrapping paper makeup the tubes. They are made

right on each strut, cement being applied between each layer of paper for

stiffness and strength.

The tubes are cemented to bulkhead #4 at the top, and

are separated from the bulkhead with 3/16" thick blocks at their lower

ends. As shown in the sketches, triangular gussets are cemented to the

tubes at the upper and lower ends to take up landing shocks. A small area

around the tubes should be filled in to provide extra strength. In the

sketch of the tail end of the fuselage under the side view, note that

there are hard balsa slabs cemented to the inside of the fuselage where

the 3/16" dowel passes through, as this portion must be rigid to take up

twisting strains and the forward pull of the motor.

We used a rod of some plastic material like celluloid

to anchor the rear end of the motor, but a wooden dowel will do, besides

being more readily available. The 1/8 x 1/4" strips on the rear of the

fuselage should be cemented in place now, followed by piece R-10, the top

of which, should be flush with the top of the 1/8 x 1/4" strips. Cement

R-9 in place now, and cut out a # 1 bulkhead from1/32" plywood, which is

also cemented

in position. The fuselage is now covered with small

squares of tissue, with the grain in the tissue running around the

fuselage instead of parallel to the longerons, as commonly applied. Use

small squares of tissue, about 4 x 4" on the front of the fuselage, as the

curves are too sharp to allow covering with larger sheets. Larger sheets

can be used near the tail (#12 to #16) as that portion of the fuselage is

nearly flat, and almost half of the fuselage side can be covered with one

piece. If your technique "isn't so hot," use small sheets throughout, as

much neater results can be obtained that way.

Landing Gear. A full-size wheel detail is given

for those who wish to duplicate the original "hubless" wheels. Procedure

is simple. The disks #1 and #2 are cemented together first, followed by

the insertion of the short tube, which is cemented and recemented to #1

and #2 until there isn't any more room left for more cement. The wire axle

is inserted now, and a small metal piece "X" is soldered on. Disk #3 is

hollowed out slightly in the center to allow space for the axle and piece

"X." The wheel is now sanded to shape and doped with several coats of

clear dope. The axle is now cemented to the bamboo strut, bound with

thread, and cemented over again with another coat. The bamboo struts

should slide into place snugly enough to make sure that they do not drop

out in flight, as that is not allowed in contests, whether it is

intentional or not. A few coats of dope will make the struts a snug fit if

they are loose.

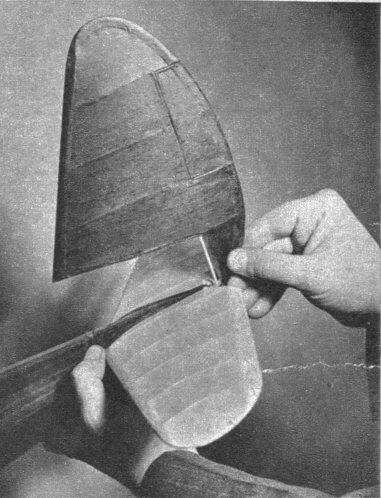

Stabilizer. The stabilizer is of ordinary

construction, except for the fact that, like the wing, heavy leading and

trailing edges replace spars. The small former "S" fits under bulkhead #16

when the stabilizer is in place, and "S-2" is of the same shape and height

as #16. Small stringers are used to fair in the top of the stabilizer with

the fuselage, but they should be added only after the stabilizer has been

covered. While we are on the subject of covering, a few hints on the wing

covering should be timely. The wing has an intentional warp in both

panels, and by covering the wing with the grain of the tissue running

chordwise, the warp as used in the original model can be duplicated. When

the tissue has been applied and sprayed, the panels are laid down flat on

the bench and weighted down with small objects, such as an ink bottle,

pliers, or anything that does not weigh more than about eight ounces. The

entire leading edge should be resting on the bench, but the wing-tip

portion of the trailing edge should be propped up 1/8" near ribs 18 or 19.

The center section of the trailing edge should be touching the bench the

same as the leading edge.

After the tissue is dry, the wing should be removed and

doped on the undersurfaced part, this being done with a 3/8" wide brush

for speed. The wing should be weighed down the same as before, and the

upper surface doped. After a long period of drying, the wing should be

removed to check up on the warp. Whether it is warped or not, the above

doping procedure should be followed with two more coats. After the last

coat, the panels should be left in the weighed-down position overnight to

make sure that the warp doesn't fade away after the wing has been removed

from the bench. If you are not successful in obtaining a warp in the

wings, do not worry about it, as the model flies slowly under power. You

need not worry about a stall under the initial burst of power, as a little

right thrust will correct that. The purpose of the warp is to decrease the

drag of the wing tips while gliding, as the wing is always at an angle to

the airflow.

Rudder. All curved parts and ribs are given full

size. Note how the hinges are made. The best material for hinges is

aluminum, as it bends easy and is light. It is important that the ends of

the hinges be twisted, as the trimming tab may slide off the hinges if

they are left straight. Ordinary cement does not hold onto aluminum very

well, as there are no large pores for the liquid to seep into and get a

grip on.

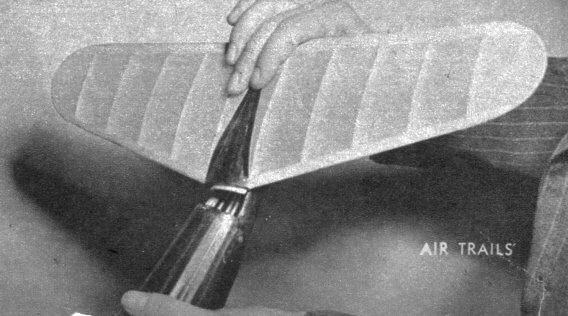

Propeller. The propeller is carved in the usual

manner, using the layout on the plans. The undercambered portion of the

prop blade need not be carved away excessively, as the original had but

3/32" undercamber. After covering with silk and doping, two small blocks

on each side of the prop should be carved into a spinner, the rear of

which is hollow to contain the free-wheeling unit. A full-size cross

section detail is given, so all shaft and freewheeler parts can be bent to

shape directly over the drawing. The front of the shaft is bent to shape

first, starting with the winding loop. A small brass washer is soldered on

the shaft behind the loop. Before sliding the prop into place, a tube

should be inserted through it or bushings used to insure smooth rotation

when the prop is freewheeling. The wire piece "U" is soldered in place

next, after the prop has been slipped into place. After piece "L" is in

place, twist the shaft clockwise (looking from the rear) to see if you can

make "L" and "U" lock, as it should be under power.

Bend the front end of "L" over now to keep it from

slipping off while you worry about the rest of the model. A ball-bearing

washer is used behind "U," behind which the nose plug belongs. The nose

plug is made from very hard balsa cemented together and also clamped with

a threaded bushing. A bobbin slipped in place before completing the hook

at the rear end of the shaft completes the prop assembly. For those who

have been wondering why, the bobbin is used to keep the motor from

bunching up on the shaft, an evil quite prevalent when the plain type of

hook was used. Since the wing cannot be shifted forward or backward in

adjusting, a weight which can be moved at will is attached to shift the

center of gravity a wee bit for perfect adjustments. A sketch accompanying

this article should help to clear up the idea. The climb should be long

and gradual and the glide flat. On the original model, the fourteen

strands of 1/4 x 1/30" rubber kept the prop spinning for 1-1/2 minutes,

after which the model glided for 2-1/2 minutes, producing an average

flight of approximately 4 minutes' duration. The maximum number of turns

is 1,200, under ideal conditions.

BILL OF MATERIALS

(Balsa, unless otherwise specified)

| 2 pcs. |

1/16 x 3 x 36" hard balsa |

bulkheads, wing channels |

| 1 pc. |

1/32 x 2 x 2" plywood |

former #1.

(1/20" plywood will do.) |

| 24 pcs. |

3/32" sq. x 36" medium balsa |

longerons |

| 2 pcs. |

3/32 x 1/2 x 36" soft balsa |

fill-in material |

| 1 pc. |

3/32 x 7/16 x 18", |

stabilizer trailing edge |

| 2 pcs. |

1/8 x 1/4 x 11-1/4" bamboo |

landing gear struts |

| 1 pc. |

1-3/4 x 2 x 18" medium-hard balsa |

prop block |

| 4-2/3 ft. |

1/4 X 1/30" brown rubber |

|

| 3 pcs. |

1/20 x 3 x 36", |

wing, stabilizer and rudder ribs |

| 1 pc. |

1/4 x 5/16 x 18" |

stabilizer leading edge |

| 1 pc. |

1/16" sq. or round bamboo, 18" long |

stabilizer tips |

| 1 pc. |

1/4 x 3/8 x 7" |

rubber leading edge |

| 1 pc. |

1/4 x 5/8 x 6" |

rudder base rib |

| 2 pcs. |

1/32 x 3/16 x 1-1/2" aluminum or brass |

rudder binges |

| 1 pc. |

3/32" diam. bamboo or dowel |

rudder spar |

| 1 pc. |

1/8 x 2 x 6", medium-hard balsa |

wing tips |

| 2 pcs. |

3/16 x 7/8 x 22" |

wing trailing edges |

| 2 pcs. |

9/16 x 5/8 x 22" |

leading edges |

| 1 pc. |

3/16" diam. x 2" long dowel |

rear motor plug |

| 4 pcs. |

1/16 x 2 x 2" |

disks #1 and #3 on wheels |

| 2 pcs. |

1/8 x 2 x 2" |

disk # 2 on wheels |

| 1 length |

1/16" diam. spring steel wire |

prop shaft |

| 1 length |

.040" diam. spring steel wire |

"U" and "L" fittings, wheel axles |

| 1 |

bobbin |

|

| 1 |

ballbearing washer |

|

| 1 |

threaded bushing |

|

| 3 sheets |

colored tissue |

|

| 2 |

bushings for prop

(or 1/16" inside diameter tubing) |

|

| 2" length |

tubing |

to fit over axles and fitting "L" |

Scanned from April 1940

Air Trails

|