|

Let's fly with

"SNOOKY"

Spring's just around the corner. And that's a natural

invite to all outdoor modelers. Take "Snooky" along with you and watch the

fun begin.

BY LEON FRIEDMAN AND

ARTHUR RUTHLEIN

|

This enlarged shot shows the model still climbing after reachingan

altitude of 400 feet. Rudder is set for wide circling. |

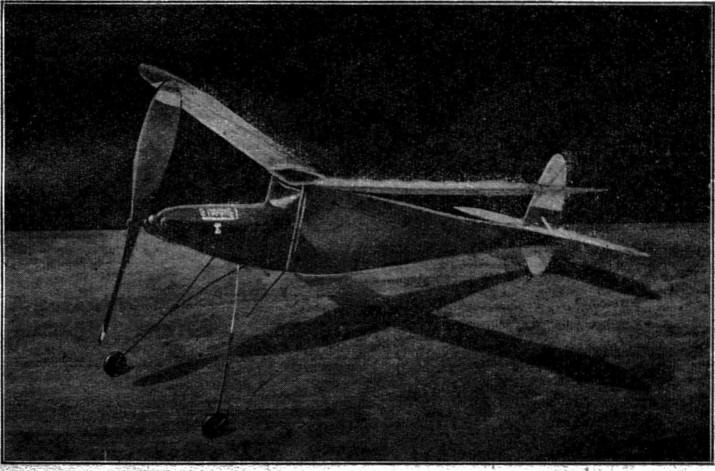

Power packed, this outdoor cabin job averages flights of more thanfive

minutes. The glide is increased with an F-W propeller. |

|

The landing gear is set well forward to absorb

the shock of head-on crashes. |

THIS CABIN JOB was built for two purposes. First, to

give its builder all the fun and pleasure that should be expected from a

well designed ship, and second, to demonstrate to those interested

bystanders that they too can indulge in the sport of model plane flying.

This craft, which is capable of twelve minutes high

time, has won several contests held between two New York high school aero

clubs. And now, without going into any further description of its virtues,

let's start right in by checking our Bill of Materials and begin

fabrication of the powerhouse.

FUSELAGE CONSTRUCTION

OUR BODY, or powerhouse if you choose, is constructed

entirely of 1/8" square longerons, cross braces, and diagonals. The first

step is to draw a full size working plan with the position of the

longerons and compression members drawn in heavier lines.

Pin down the top longeron. Cement the break required

for the cabin roof. The lower longeron is slightly curved and held into

position with the aid of ordinary shirt pins. Pin down the short nose

horizontal piece. Next, cut all the required compression members necessary

and cement each one snugly into position. Apply glue along the joining

surfaces, too. Note that the compression members extending from the lower

longeron to the cabin roof are single lengths. Add the angle of incidence

strip to the top longeron with glue.

After the first side is completed, repeat the

construction procedure for the second side. Both sides are then joined

together by cross braces cut to correct sizes from. 1/8" square hard

balsa. Careful, but definite breaks are made in each frame just in front

of the cabin and at the rear. Add the cross braces at these points first

and cement. The remainder of the braces are added from the rear of the

cabin down to the extreme tail end.

NOSE AND COWLING

FULL SIZE formers for the nose section are given in

Plate 2. Use soft balsa for each one required and cement in their

respective positions designated by the side view stations. The nose piece

is then covered on both sides and top with 1/32" sheet balsa. Use cement

generously along the sides of the compression members and rounded tops of

the formers. Press the sheet wood down firmly and insert small pins part

way into the wood temporarily. Later, they are removed. The cabin windows

and curved windshields are made with thin sheet celluloid.

The nose plug is shaped as required from a hard block

of balsa measuring 1/2" by 1-1/2" by 1-1/2".

After sanding the smooth finish necessary, place the

nose piece flush against the nose and with a pencil, mark from behind the

outlines of the fuselage frame opening against the rear of the nose piece.

Use 1/8" square hard wood cut to the necessary lengths to make the rear

ledge. When dry, fit the nose piece into the nose of the body to test for

a snug fit.

To make the two front hooks, use a pair of half round

nose pliers to shape the fittings out of .024 music wire. Insert firmly as

shown in the side view, and dab with a bit of cement. A notch is cut into

the upper part of the removable nose plug. This is clearly depicted by

both side and top views of the plug on Plate 1. It is made deep enough so

that a rubber strand will rest within it undisturbed. The strand is

knotted into each wire hook and fits diagonally across and into the plug

notch.

LANDING GEAR AND TAIL BOOM

SHAPE THE landing gear legs with the aid of the half

round nose pliers. The main gear has a 5" extension on each side of the

body. The horizontal part is set flush to the fuselage bottom cross brace

and wrapped securely with strong thread and cemented. Be sure the thread

is set to measure 9" across. The rear short wire extension is attached to

the body in the same manner and bound as illustrated. A half curve of wire

is attached between the main extensions and bound as illustrated. Rubber

tired or hard wood wheels may be used depending on the choice. The landing

gear has been designed to withstand the severest bounce. When the lauding

gear is completely set to function, cover the underside of the nose

section with 1/32" sheet. The entire nose is then given three coats of

clear dope with a light sanding after each application is thoroughly

absorbed. The cabin roof also is covered with 1/32" sheet. This piece lies

flat between the longerons -- not on top of the incidence strips.

The side view of the tail boom as well as the

perspective sketch depicts the method in which this removable section is

made. The actual frame is made up of 1/8" square material joined with

compression and cross members. A solid tail block measure to fit, is

cemented snugly into the frame as shown in the rear view perspective on

Plate 3. The rear hook is shaped from .040 music wire, inserted bent again

and pulled tight. Dab cement all about to insure a permanent fixture.

The tail boom is held to the fuselage by means of hooks

shaped from .024 music wire. Eight small hooks are required. Insert each

one into the longeron, above and below and apply a bit of cement. Cover

the section with sheet balsa as required.

The rudder underslung is shaped from 1/8" sheet and

sanded to a streamline. The lower tip is guarded with a strip of 1/32"

square bamboo which is cemented in the position shown. The underslung is

not attached in place until the detachable boom section is paper covered.

WING AND TAIL

WHEN tracing rib number 1, trace it completely

including the leading and trailing edge spar. This insures a true airfoil

section. Next, mark off the positions of the aforementioned spars

including the center spar and cut out with a razor.

Make the first template out of hard balsa slightly

undersized. The pencil line used to obtain its correct curve makes up for

the difference. Cut out the required amount of ribs as well as the last

two wing tip ribs. The break for the dihedral angle is made aft of the

center rib -- or at the position for rib one -- right and left of the

center. Raise the spar tips to 4". Place props at each tip while the

cemented spliced center spar dries.

Proceed in the usual manner of wing layout. Note that

the spar tapers slightly aft of rib 3. Add the leading and trailing edge

spars. Round and taper as required to obtain a true airfoil section. Wing

tips are sanded to shape and cemented well. The center section is covered

above and below with 1/32" sheet.

The construction of the stabilizer is as simple as it

appears. The leading edge which is made of 1/8" by 1/4" balsa is sanded to

obtain a round face. The tips are tapered from l/8" sheet balsa. The cross

pieces and diagonals are cut to proper size from 1/8" square stock and

cemented well. The trailing edge spar is tapered so that the cross

sectional view of the stabilizer appears to be streamlined.

The framework of the rudder is similar to that of the

stabilizer. Cement all joining ends well. The rudder tab may be cut to

shape from either stiff manila paper or thin sheet aluminum. The latter,

however, is more reliable. The tab is inserted into a slit made in the

trailing edge of the rudder and cemented.

COVERING AND DOPING

USE THE BEST grade Jap tissue to do the covering job. Apply the paper in

the conventional manner. Leave a 1/4" margin on the section pattern. The

dope should be a thick but clear variety. Work slowly and pull the paper

tightly so that no wrinkles set in. The balsa covered section of the nose

is also covered with tissue. When fuselage, wing, and tail parts have been

covered, water spray lightly and allow to dry under normal temperature.

The dope is applied with a soft brush. For shrinking,

the dope should be thinned out to a workable consistency. One coat will

probably do the job well enough.

FREE WHEELING PROPELLER

A FREE WHEELING propeller decreases the drag set up by

a stationary one. The simple arrangement shown on Plate 3 is made by

following the sketches illustrated. The prop should be carved from a hard

balsa block. Bend the required shoots as shown, insert and cement. A ball

bearing washer may be placed on the rear of the prop shaft before the rear

loop is closed. This washer gives smoother revs and increases the speed

also.

Check the prop for balance. Apply a few coats of thick

dope on the prop and sand lightly between each coat. Attach the engaging

hook as illustrated and cement where necessary. The prop may be painted

with any colored dope chosen. It also acts as a preservative.

ASSEMBLY AND FLYING

RUBBER LUBRICANT may be made by using green soap

particles mixed with 10 drops of glycerine. Rub this mixture well into the

rubber strands. Afterward, arrange the power strands so that they fit

between the prop shaft and the rear hook. Always keep the rubber clean and

well "lubed."

The stabilizer is cemented flush to the detachable boom

piece. The rudder is cemented upright. Check both surfaces for right angle

alignment. When dry, affix the plug in position and bind to the main

fuselage with small rubber bands. The wing is held to the cabin with

rubber bands. It should be held to the roof snugly but not too tight.

There should be a certain amount of "give" in the event the ship hits any

object.

Counteract warps that have set in by blowing your warm

breath over that portion and twisting it back to its normal shape. Glide

test the ship first. If the "bugs" crop up, more glide testing and short

power flights will bring out the beast or bird in it. Use the rudder tab

for slight turns. Do not increase the twist on the tab more than necessary

to make a gentle turn. Too much rudder on a gentle bank causes slipping.

For longer lasting flights, use a mechanical, winder.

THE END

|

BILL OF MATERIALS

Thirty-six feet 1/8" flat brown rubber for power strands

Twenty-five pieces 1/8" sq. by 36" hard

balsa for fuselage longerons, etc.

Four pieces 1/8" by 1/4" by 36" medium

hard balsa for wing and tail parts

Four sheets Japanese tissue for covering

Three lengths .040 wire for landing gear, etc.

Two pieces 3/16" sq. balsa for wing parts

Two large-faced bushings

One piece 1/16" by 3" by 36" balsa for

wing ribs, etc.

One piece 1/8" by 2" by 36" balsa for wing

and tail parts

One 1/2" by 1-1/2" by 1-1/2" hard balsa

block for nose piece

One 1-1/8" by 1-1/2" by 14" hard balsa

block for propeller

One 1/32" by 3" by 36" balsa sheet for

covering fuselage parts

One length .024 wire for hooks, etc.

Dope, cement, rubber lubricant, sandpaper,

knife, razor, wheels (rubber or wood) celluloid, nose pliers, and

cutters. |

Scanned From April, 1941

Flying Aces

|