|

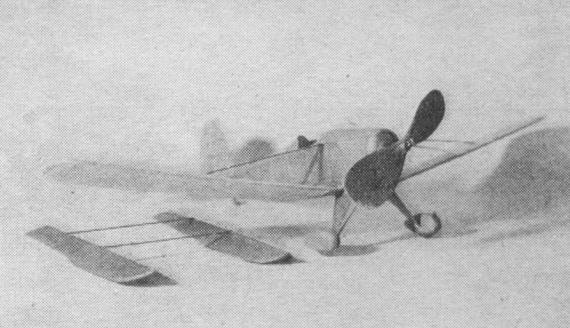

With Wheels Or Pontoons A Flying Scale Model of the Arrow Sport Plane The Arrow Model F by Alan D. Booton

FOR the simple reason that stock automobile engines have decreased in weight and increased in horse power and dependability during the past decade, it takes but little imagination to foresee mass production of safe, low-priced plane designs -- powered with the coming lighter and higher-powered, easily converted automobile engines -- in the next decade. The surplus planes from the World War are seldom seen outside museums, and the flock of medium-sized, second-hand planes are diminishing rapidly, so the fellow who is eager to fly his own plane is faced with the problem of finding a reasonably safe ship that is light on the purse for initial cost and upkeep thereafter. It used to be possible to build and fly your own plane, but now most States require all ships to be licensed, so that heads the prospective pilot in another direction. Years ago, Henry Ford became interested in light plane possibilities, but immediately abandoned the idea when his first venture ended fatally for his young pilot. During the past two years, several pioneering companies have attempted to place on the market, with little success, planes powered with auto engines. The use of Ford engines seems to predominate. This month, Air Trails presents the Arrow Model F. The Arrow, powered with a converted Ford V-8 engine rated at 82 h.p. at 3,075 r.p.m., climbs 500 ft. per min., does 90 m.p.h. full out, cruises at 85 m.p.h., and lands at 45 m.p.h. with flaps down or 48 m.p.h. without flaps. The model is of conventional design and is very easy to build. After the model was tested and the stolid stability noted, the author decided to include the scientific float design for the readers' benefit. FUSELAGE Place waxed paper on the drawing to prevent sticking. A bread or drawing board makes an ideal surface to work on. Build two sides of the fuselage frame of 1/16" sq. at the same time and split them apart with a razor blade when dry. Starting front the rear, cement in the 1/16" spacers, according to the top view, and keep sighting through the frame, so warps can be prevented. Cement the formers to the stations indicated. Cement 1/32 x 1/8" strips to the inside of #9 to extend to the back edge of #10, to form the plug effect. Cement the rear hook to #10 with a piece of 1/8" sq., in the position shown. Separate the rear portion of the fuselage with a razor blade. Cover the fuselage completely between #1 and #1ab and #2t, then the top of the fuselage back to #4t, leaving the cockpit, then the top of the removable rear end, with 1/32" sheet balsa. Carve the nose block and cement the 1/16 x 1/8" strips on as shown on the nose block detail. Insert a double bearing (if you prefer) in the nose block. The bearing is made of one length of 3/32" alum. tube to turn freely. Knurl the end's of the 3/32" tube to hold the 1/16" tube in. Bend the double-acting landing parts and cement them to the fuselage. Note that the #14 music wire extends from axle to axle and the #10 music wire is only bent over the #14 music wire. As the #14 music wire part is bent, be sure to include the 1/16" tube bearing. This bearing is heavily cemented to the rear - bottom edge of #3b. A length of 1/8" flat rubber forms the inner struts and is installed with considerable tension. Attach the tail wheel with a #8 wire fitting shown in detail. An easy way to install the wheels in the pants so they may be attached to the axles without "fiddling" many minutes, is to cement 3/32" alum. tube bearing's in the wheels and then mount the wheels in the pants on 1/16" alum. tube. The pant - wheel unit can then be quickly placed on the axle. WINGS AND TAIL SURFACES Assemble the wing panels on your work board, using plenty of pins to beep the many parts lined up. Complete the frames before removing. Cement the #14 music-wire prongs to the wing spars and, when dry, push the plain ribs (C. S. ribs) on the prongs of each wing up to and flush with the first ribs. Now attach the wing frames in position against the former extensions, forming the center section. It is best to block the fuselage up in neutral attitude (level), then pin and block the wing frames in place. Slip 3/4" lengths of 1/16" alum. tube on the prongs and then cement the tubes and the plain ribs to the former extensions. While the blocks and pins are still in place, make the struts and the #8 music-wire clasp fittings as shown in detail, and cement them to wings and fuselage as indicated. The dihedral angle should be approximately 2". Assemble two halves of the stabilizer and cement them to the detachable fuselage end. An auxiliary spar slot is provided in case you prefer to build the stabilizer as a unit, which is better. Assemble the fin-rudder frame and cement it on in neutral position. The 1/16 x 1/8" tail-surface ribs must be sanded to streamline before covering. FINISHING THE MODEL Dismantle the blocked-up frames and cement 7 1/32" bamboo fairing strips to the top of the fuselage, as shown in the drawing. Cover the fuselage frame and fin-rudder frame with red tissue, including the balsa-covered portions. The pants and landing-gear struts are covered with red tissue, also. The wing and stabilizer frames look well when covered with orange tissue. After the model is completely covered, attach the tail-surface bracing and spray the tissue with a fine mist of water. This tightens the tissue when dry. Now brush the whole model with two coats of thin model dope or good banana liquid. It is best to have the wings mounted on the fuselage while doping. Now is the time to add all the detail, such as the windshield, the head-rest fairings, radiator, lights, license numbers, etc. PROPELLER AND POWER Carve the propeller according to the pattern on Sheet 4. This is an unusually wide design, but provides for longer flights. Sand and dope the blades to a high polish. Attach the propeller to the nose block: fit the free wheeling, shown in detail, or one of your own design. Three loops of 1/8" flat rubber is enough power for the model as a land plane and should be enough for the model as a seaplane. The original model weighs 1.5 oz. as a land plane and 1.6 oz. as a seaplane. No change in power was needed when the original model was changed to a seaplane. FLOATS The float design is very simple and light, but important. Note the "hook" forward of the step and the bottom angles of the hull, fore and aft of the step, also the wide prow that minimizes digging in the water on steep landings. To preserve the important shape, cover the portion of the bottom forward of the step with 1/64" sheet balsa. After both frames are made thus far, cover them completely with red tissue, shrink them with water and, when dry, apply a coat of model dope and then a coat of clear or red lacquer to waterproof them. Cement 1/8" sq. x 6" streamlined spacers between the float centers and add the necessary wire parts to make them attachable to the model. The tops of the floats should be parallel with the top longeron of the fuselage when attached. FLYING THE MODEL Balance the model longitudinally one third back from the leading edges of the wings. Glide the model into tall grass, until the resulting adjustments are satisfactory then make full-power take-off tests in a field free of obstructions. After the land-plane version performs well, attach the floats and check the balance again. If the balance is the same, the model is ready for the initial water takeoff. Do not get discouraged by the many duckings that will occur. The thrill of many happy take-offs and landings on water is well worth the trouble. MATERIAL LIST

Scanned From May 1937 |