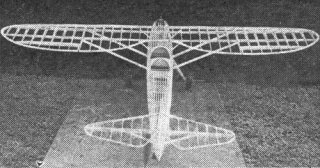

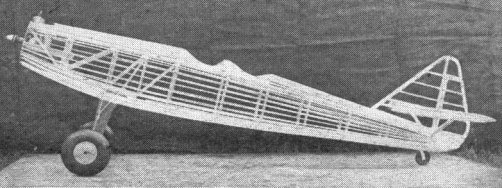

| Construct Our Gas-Powered Douglas O-41A

By Frank Roberts

GULL - WING observation planes built by Douglas have been used by the Army in several different models and types. Some have had wire-braced wings, some are strut-braced. Radial engines have been installed in many of the models, and the in-line power plants have been used in others. The Douglas O-41A is one of the later types, strut-braced and powered with an in-line engine. Because of its fine flight characteristics it lends itself very willingly to reproduction in reduced scale as a gas-powered model. The original ship has a wing-span of about 45 feet and a fuselage length of 40 feet. Thus the fuselage is quite long for the span, and this feature adds definitely to the stability of a model. Our flying scale model, which except for very minor changes accurately follows the big ship's scale, has a span of 49-7/8 inches, a length of 36-3/4 inches, and weighs but one pound and seven ounces. It was designed to fly with any of the standard miniature motors. The drawings show the installations for the Syncro Bee and the Trojan Junior. The bases for these engines differ slightly, and since they are generally representative of the small motor field they can be used as guides for the fitting of any other motors in the group. While building models from these plans and instructions, some sharp-eyed modeler may note slight differences between the plans and the accompanying photographs. The reason is that the model as shown in the picture was built from working drawings, then tested and photographed. Finally the finished drawings for FLYING ACES' reproduction were prepared to include any changes indicated by the tests. The rule, therefore, is to follow the photographs for general reference and the drawings for accuracy. The model is surprisingly easy to build, and any modeler of fair experience should have no trouble. Remember that most sections of the model are covered in the plans in three different ways -- top, sides, and front. Therefore if you don't see what you need on one plate, refer to one of the others and you'll find the answer. Formers and ribs are given in full size on Plates 3 and 4 respectively. Other features are of necessity reduced and must be enlarged to twice their size. Of course, only the outlines actually needed in shaping need be enlarged. To build the wing, for instance, the only "blow up" needed is the main outline on Plate 6. When the enlargements have been made, fasten the sheets down to a suitable work-board or table top on which they can safely be left between working periods. Cover them with heavy waxed paper to protect them from cement, for much of the assembly work is done directly over the drawing. And now if you'll take the Bill of Materials down to your nearest dealer and get the necessary supplies, you'll be all set to start work. CONSTRUCTION OF WING SINCE it's a good idea to do the hardest work first, I like to begin with the wing. The ribs may be traced directly from the plate onto the 3/32" sheet by means of carbon paper, or the patterns may be traced and cemented to light cardboard and then cut out for use as templates. The ribs are of accurate Clark Y section. Care should be taken to cut them accurately, cutting the notches to the exact depths indicated. The trailing edge is cut from 1/8" by 2" sheet and the tips from 1/2" sheet. Spars are made from 1/8" by 1/2" and are pinned directly over wing drawing. The ribs are lined up on the spars before cementing them in place. Accurately cut, the notches in the ribs automatically give the wing the correct taper (when viewed from the front). Any slight adjustment in the ribs should be made now. Trailing and leading edges can be installed as soon as the ribs have been cemented to the spars. Spars are trimmed flush with the bottom of the ribs after the wing is assembled. After the wing is dry, cut in the ailerons and cement the aileron spars in place. Spars and leading edges are joined at No. 3 rib. Do not cement these joints until the wing has been assembled and the proper dihedral is given the wing. Note the brace blocks on each side of the spars. See the front view on Plate 5 for dihedral angle. The amount given is only the scale amount, which I believe to be enough. However, some modelers may prefer to increase the angle according to their own ideas. The leading and trailing edges and spars should now be trimmed down to a neat streamlined finish and taper. Use a block of wood, say 1" by 3" by 12" wrapped with fine sandpaper. Finally, cover the wing with silk or heavy tissue. Silk is not only the easiest to use, but it is the strongest of all coverings, too. TAIL SURFACES THE tail spars may be tapered before the ribs are cemented in place. However, I prefer to build the tail units with the spars as wide as the widest part of the structure (center rib on stabilizer, bottom rib on fin), and all the tapering done with woodplane and sandpaper after assembly. Hinges for the tail -- and also for the wing ailerons -- are short pieces of soft iron wire. Insert them at the center line of the spar and cement them at each rib (refer again to Plate 6). Insert the stabilizer into the fin before hinging the two elevators onto the stabilizer. FUSELAGE ON Plates 1 and 2 you'll find the main frame of the fuselage indicated on the side and top views by shaded lines. This frame -- with its uprights, crosspieces, and diagonal braces -- forms the box-like skeleton on which the formers are cemented. It takes all the strain of motor, landing gear, and struts. The main frame is built of 3/16" square hard balsa. Build two sides exactly alike. Complete the frame by cementing the top and bottom cross-pieces in place, starting at Station No. 2 and working toward the rear. Rubber bands and pins are used to hold the sides together while the cross-pieces are being cemented in place. No. 1 former is cut from 1/8" plywood and cemented in place first. If you intend to use a motor other than either of the two mentioned, you will have to change the motor bearer notches to suit. Check the frame for squareness and true curve of each side. Any irregularities may be taken out by holding the frame in the steam from a kettle for a few minutes and then blocking the frame in the correct shape and allowing it to dry. Make and install the landing gear at this time. Music wire of 3/32" diam. forms the basis; bend it as shown by the sketch on Plate 5. The joints are bound with soft wire and soldered. The assembly is cemented to the fuselage frame and cross-braces, then wrapped with thread and given a second coat of cement. The 3/8" wood is cut to the shape of the pattern and each piece is grooved 3/64" for the wire. The strut halves are cemented together with the wire sandwiched between them. The wooden part of strut is not cemented to the fuselage or wing strut. Instead, a slight space is left clear to allow the gear to flex for landings. The former patterns are used in somewhat the same manner as the wing rib patterns. Do not cut out the notches at this time, but mark the places where they should come. As the formers are cut out, they may be cemented in place on the top, bottom, and sides of the fuselage frame. When the formers are all in place the stringer notches may be cut; a piece of fine hacksaw blade answers very well for this job: Check the frame again for squareness and accuracy, then cement the stringers in place. The space above the main frame between Formers No. 5T and No. 7T is covered with 1/16" sheet balsa. Cockpits are cut in after the sheet is cemented in place. If the modeler wishes, this entire section could well be made removable to allow easier access to the coil and battery. In the test model of our Douglas O-41A, I used an Austin-Craft battery holder fastened to a pine strip 1/16" by 2" which was cemented to Former No. 7. Some modelers may wish to use the larger size holder fitted in a horizontal position, shifting it for flight balance. My flight timer was installed just back of No. 7 former. The position of the timer, batteries, and coil will of course depend upon the weight of the motor used, the weight of the material used in the model, and other factors. The only sure method of locating them correctly is to complete the model (including the doping) before installing these items. The balance point should be approximately one-half inch ahead of the rear spar. The No. 2-1/2 and No. 3-1/2 "formers" are cemented to the bottom stringers and covered with 1/32" sheet balsa to form the dummy radiator, the front of which is made from 1/8" balsa cut to the shape shown on the front view (Plate 5). These radiators under the fuselage may be omitted from the model if desired. The square between the No. 2 uprights and cross-pieces is filled with a piece of 1/8" hard balsa in which is cut two 1/4" by 1/2" holes for the motor bearers. If motors other than those mentioned are used, you will have to rearrange these holes and the corresponding ones in Former No. 1. The centerline of the motor shaft should coincide with centerline of the fuselage. Pine bearers of 1/4" by 1/2" stock are used for the motor mount. The motor may be screwed or bolted to the bearers. The Trojan Jr. is refueled from the bottom, so it is necessary to have the lower portion of the fuselage removable as well as the top. For the Syncro Bee motor only the top needs to be removable. In all cases it is well to have a few holes in the bottom of the motor compartment to allow the escape of gas and oil that drips from most power plants. Propeller data need not be given here, since it varies with the engine used. Merely follow your factory recommendations. COVERING CONTRARY to the popular notion, silk is more easily applied than tissue. To apply silk, cement one end in place and pull the other end until the material is taut (but not too tight). Pin it in place and stretch it sidewise, then adjust until all wrinkles are out and the threads are straight. Apply paper cement over the silk and press the material into contact with the rib or frame with your fingers. Only the outer edges of any panel need be fastened. Trim off when the adhesive is dry, and lightly sandpaper the edges. Spray with water and allow to dry before doping. The model is doped with two or three coats of model dope. Correct colors are yellow for the wing and tail, and blue for the fuselage, landing gear, and struts. Stars and insignia are standard army colors and may be bought as transfers. When assembling the model, cut the covering away wherever any strut or other part must be attached. The center-section struts are cemented to the fuselage at the start. Note the 1/32" music wire supports that run across the fuselage and up the struts to the spar or ribs, where they are cemented. The wing is cemented on the center section struts. Care must be taken to install it at right angles to the fuselage. See that the angle of incidence is as shown on the side view. Cement wing struts in place. The windshield is made from celluloid over wire supports. And now, if you have carefully followed these instructions and have used your best workmanship on the job, you will have produced a fine-appearing flyer of great stability. However, if you should run into any difficulties during construction or flying, I'll be glad to help you with them. Write me in care of FLYING ACES Magazine, 67 West 44th St., New York, N. Y. And be sure to enclose a stamped, self-addressed return envelope if you wish a personal reply.

Scanned From December 1938 Flying Aces |

|||||||