|

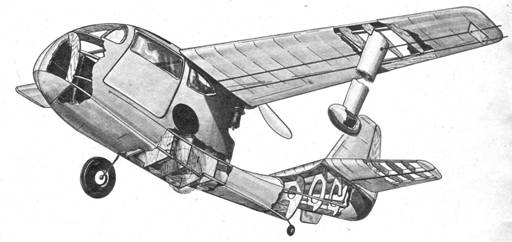

‘SEABEE’ by MARSHALL S. GREEN

FOR the many control line fans who

get a real kick out of realism, no greater thrill can be experienced than

piloting this miniature of Republic's smart, new, personal amphibian. This

particular scale model has been designed to take off and land on water, which

in itself constitutes a major incentive to build it. Since drawing up the first set of plans many

revisions and structural simplifications suggested themselves; these have

all been included here and it is thought that anyone with a little model building

experience will have no difficulty in following the drawings and the text. LAYOUT—Having fastened a

40" x 60" piece of clean, uncreased brown

wrapping paper onto the dining room table with scotch tape, start by laying

down the centerline for the plan view and the base line for the elevation and

then completing the two grids of 1/2" squares required for each view;

be exact and keep the lines parallel, for upon accuracy depends the fit of

all formers and bulkheads and the ease with which the hull can be finally

sheeted. With the aid of given dimensions and the grid,

draw up the elevation (side view) and plan, flow in the curves smoothly with

"french curves" and "sweeps,"

if available; if not do the best possible by freehand for small curves and,

for the long sweeps, a straight grained piece of 1/8" x 3/16" hard

balsa strip in place of a regular "spline."

The balsa spline works every bit as well as a

Copenhagen ship sweep and has the extra advantage of being adaptable to any

desired contour. Despite the fact that neither side view nor elevation is

used in actual construction of the hull, they are imperative for checking the

accuracy of bulkheads and as a guide to the shape of nose block, formers,

engine nacelle, as well as for building the empennage.

HULL—Lay

out bulkheads as shown, transfer all but Stations 1 and 6 onto medium

1/8" sheet. Bulkheads No. 1 and No. 6 are cut out of 1/8" 3-ply.

Check each station with the drawing and make sure that notches for strake,

chine and stringers are accurately located. Bulkhead No. 4a has cemented to

it a block made from a piece of 1/2" thick oak, maple or similar

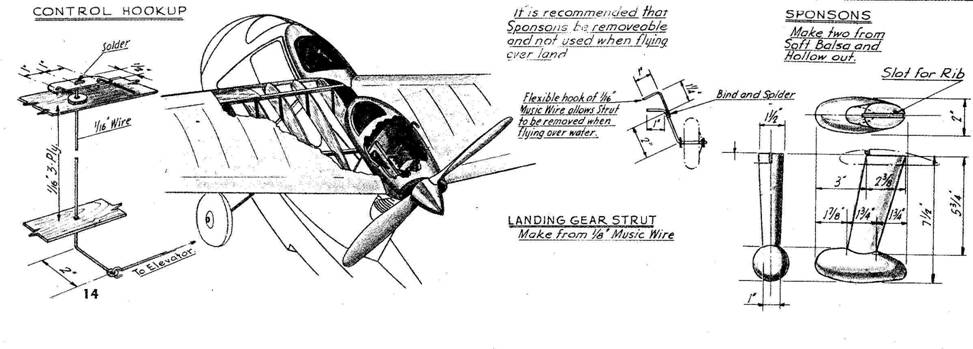

hardwood in which two holes are drilled as shown. The landing detail gear on

sheet No. 2 should explain the function of the block. Actual assembly can now start. Unlike the majority

of models which are built over the plans in the initial stages, the contours

of the Seabee made this impractical

and the construction method known as "building in air" was resorted

to. This means that excepting for the keel and flying surfaces which can be

assembled directly on top of the drawing, all structural components starting

with the bulkheads are added and cemented in place while the structure is

held free from the construction board. Check perpendicular inclination of bulkheads

against the layout and sight along keel, fore and aft, to see that they are

in perfect alignment behind each other. Lay in 3/16" square chines

and sheer beams, formers, wing platform, etc. to complete the basic

structure. Then, with the sketch on sheet No. 2 as a guide, make up the

control mechanism and install it in the hull. Make sure that tie-rod to the

elevator does not bind on any of the bulkheads it passes through. Cut out

sea-rudder from thin alum. and attach it to the

keel. EMPENNAGE — Before sheeting the

hull it is recommended that the stab and elevator be made and assembled complete

with hinges and control horn. The only uncoventional

feature of the empennage is the inverted stab which is sanded to an

approximate Clark-Y type of profile after assembly. Cloth elevator hinges are

quite satisfactory. Cement stab, elevator, fin and rudder as a unit to the

boom, then couple up tie-rod and elevator horn so that movement is smooth,

free and without excessive play. SHEETING—Were it not for the fact

that an extremely flexible piece of 1/16" sheet were used on the

original, some difficulty might have been encountered in sheeting the boom

above the strake between stations 9 and 11. However, if flexible sheet is

not at hand, this section can certainly be planked without any trouble. The

rest of the hull takes sheets in 2" widths of soft 3/32" balsa

without the remotest chance of splitting or causing any grief. Do not sheet

above former A, between stations 1 and 4; instead use strips of 1/16 sheet to

form window outlines—window aft of station 4 is fretted out of the sheet

covering. WING—Lay out the wing and cut

out required ribs from medium 3/32" balsa. Form trailing edge and

assemble each half-wing separately; when dry, fasten together with

appropriately shaped 1/16", 3-ply gussets so that each tip is raised

1-1/2" above horizontal. Apply soft 1/16" sheet to leading edge

and, if desired, 1/16" and 3/16" cap strips over each rib. From the plans, shape up the soft balsa block

which contains the window above the wing platform between stations 2-a and 4, hollow it out to save weight and cut out the

window opening. Attach this block to the l.e. as

indicated. Check contours of engine nacelle against motor to

be used before carving and hollowing. The nacelle is then also permanently

attached to the center section. In the original model the wing was cemented to

the hull, there being no transportation problems to contend with. However

the center section is so designed that the wing can be made removable if

deemed advisable. Sponsons are carved according to

the drawings and are made removable for overland flying. Reinforce ribs at sponson junction point—this was not done on the original

but the particular rib in question was made out of 1/8" 3-ply and

considered to be stout enough to stand up under imperfect landings. FINISHING — Complete the ship by

carving out the nose block to specifications and set about the task of

sanding down the 3/32" sheet "skin" with progressively finer grades

garnet paper until it is about 1/16" thick and satin smooth. Apply two

coats of filler, sanding after each coat, then follow with two coats of

lacquer or dope. Sand lightly with 4/0 wet-or-dry and then cover with a good

grade of tissue. Dope at least 4 extra layers of Silkspan

onto the bottom to insure water resistance and again use the wet-or-dry.

Finally, apply 6 coats of pigmented dope or two coats of good grade enamel

and set aside to dry. FLYING—Connect up control lines

and move ignition components about until the c.g.

falls in the location shown. Inspect the surfaces for correct trim and the Seabee is ready for its first test

flight. At the time of writing the ship has not yet been

tried on water, local ponds being ice bound, so no hints can be given of its

behavior under these conditions. From the test flights over snow which have

so far been made, the indications are that flying over water next Spring is

going to be successful. Test flying should be done with caution until best

c.g. location has been determined and the

controlling influence of the elevator properly assessed. With a motor of .29

displacement the ship flies extremely well and safely, is easy to handle and

rather slow (perhaps 25 mph), but it requires rather a long takeoff run and

for this reason it is suspected that such a small motor would not take it off

water. It was after a motor of .60 displacement

was fitted that trouble developed which needed drastic corrective measures.

The increased speed promoted a noseover tendency

which full up elevator would not overcome. Happily the ship was flying quite

low and no damage resulted. A new stab was built with an inverted section

and the trouble was entirely eradicated making it certain that no difficulty

will arise when the ship is eventually tried in its proper element. It should be mentioned that the model appearing in

the photographs has been regarded throughout the trials as a guinea pig and

no attempt was made to "dress it up." Final tests having now been

successfully concluded, the model will be finished properly. To those readers who are diehard "free flighters" it is believed that the Seabee offers something new in Class B

models. The original ship weighed 39 ozs. ready to fly, but the structure has been greatly lightened

in the plans and it should be possible to build to 36 ozs.

which will give a wing loading of about 12 ozs. per square foot. It is further suggested that the boom be

lengthened some 2" and the horizontal tail area increased by 50% to give

better longitudinal stability. Also, the wing profile should be more in

keeping with desirable free flight behavior and could better employ an

airfoil similar in characteristics to the N.A.C.A. 4412, Gottingen Sections

398 or 398R or similar high lift section. It should be borne in mind that in

all pushers c.g. location is of paramount

importance and upon its ideal location will largely depend

the stability of the ship. Much time and effort must be patiently expended

until correct balancing point is arrived at; only then may the ship be

allowed its head under full power. Scanned From January 1946 Model Airplane News |