|

STRATOSPHERE

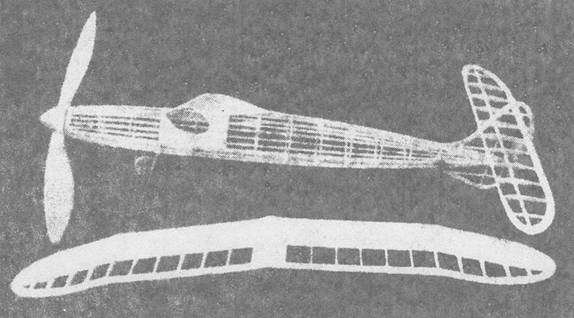

CONTEST MODEL A Super-Duration Fuselage Plane

With Extremely High Power-Weight Ratio It Has Made a Flight of

Thirty-Five Minutes

Construction of the By HENRY COLE

It’s long span and ample propeller

blade area insure long flights This model was

designed primarily for attaining high altitudes, and first

test flights were entirely up to expectations. However, after just a few

flights, the plane flew out sight and was lost. Although it set a new local

record of l8 minutes and was followed for 35 minutes.

the loss was heartbreaking because it prevented entering the model in

contests. The second test

model was improved and changed as experience with

the first one directed. Better performance was

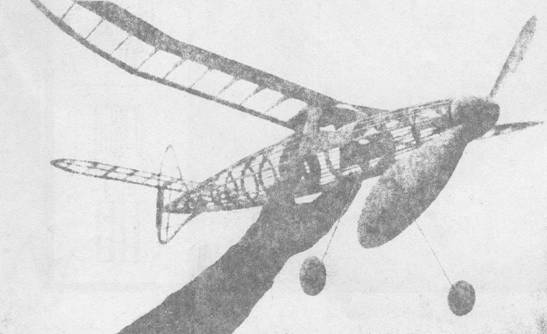

apparent immediately. Although the large prop turned slowly, the ship climbed

at a steep angle and attained altitudes as high as most gas jobs. The principle

behind this climb is simple! The ship was built extremely light and brought

up to weight rule with a heavy motor. Many model builders realize the

advantages of high power-weight ratio, but few use the extra power

efficiently. Therefore we took care to use as much stored energy as possible

towards getting altitude. A large prop and streamlined fuselage seemed to be

the logical combination. The fuselage was

especially designed to give a smooth airflow around the wing and stabilizer

as well as prevent burbles over the fuselage during the climb. The only time

the model had a chance to partially show contest ability was at a meet in

Tacoma, Washington, though a cold, gusty wind made long flights impossible. In spite of this high wind, the plane flew very

steadily and placed first with a three flight average 2 minutes. At this time

only three- quarter maximum winds was used. Later it was

found that the model averaged from 2:30 to 3 minutes with maximum turns in

calm air. We warn you, if there are any thermals around, the ship is sure to

soar away! If results with

the smaller ship are any indication, a scaled-up ship of Wakefield size

should out-perform anything in the field. If you want a super ship for 1941,

let's start construction. Fuselage At first this

type of construction may appear difficult, but with a little practice

streamlined fuselages can be made as light as the box type, and without spending

very much more time. First, a full-size drawing of the side view must be

made. For this purpose dimensions to the center line are given on Plate I. By

drawing 1/2" squares, the rudder is drawn accurately on the side view.

After this is done, the keel and rudder outlines, which are cut front medium

1/8" sheet, are glued together and pinned to the drawing. The rudder is

flat and can be completed on the drawing. Be sure that the 1/8" square

piece on which the stabilizer is mounted is parallel to the center line. While the

outline and rudder are drying, the formers should be cut. All except special

formers, are drawn full size on Plate II, giving the outside outline only.

These formers are 1/4" wide. The complete outline of the special formers

is given on Plate II. Note that the formers are cut from laminated balsa

sheet; this not only adds strength to the fuselage, but allows use of lighter

wood. Laminating is a simple process: Lay out a balsa sheet on a flat surface

and from another balsa sheet, cut short lengths equal to the width of the

first sheet. Glue these crossgrain After all

formers are cut glue half of them in place, following the outline the

drawing. When dry, lift this completed half from the drawing and glue the

remainder in place. The cabin top must be glued in place before formers can

be added, because they are glued to this top. When the formers are in place,

the 1/8" square side stringers should be glued in the notches. In order

that the fuselage be straight, stringers should be of equal weight and

strength and glued on at the same time. Before putting

on the 1/16" square stringers the landing gear and rear motor anchor

should be completed. The landing gear is secured with plenty of glue, gussets

and silk strips. The rear motor anchor is a short length of 3/16"

diameter aluminum tubing, which fits through the hole cut in the gussets

around former N. Be sure to cut the aluminum fitting shown on Plate II to

face the gussets: this adds strength and keeps tubing from pulling out. Tubing is used

for a motor anchor because a piece 1/8" wire may be slipped through it

and used for holding the model when winding. With this method no strain is

put on the fuselage when stretching the motor out to "pack

in" turns. Next the

1/16" square stringers and cabin covering are added. The position of the

stringers is marked on the formers. Note that notches are not cut for

1/16" stringers. The cabin covering is shown half size on Plate II and

will have to be scaled up. The direction of the grain is especially important

to facilitate brending. When the fuselage is finished it should be sanded

carefully in order to give a smooth covering. Wing and Stabilizer The wing has no

center spars; strength comes from the 1/32" sheet covering which also

prevents excessive sag between ribs. Full size airfoil sections are given on

Plate II. This airfoil was developed by modifying the Gottingen 176 which has

excellent characteristics at low speeds. Make a template and cut the required

number of ribs. Lay out a full size drawing of the wing and stabilizer and

construct them in the conventional manner. Taper the trailing edge before

gluing in place. After dihedral is put in cover the leading edge with sheet.

It is advisable to sand the sheet smooth on a flat surface before applying,

otherwise it will sand through at the ribs. At the center

section, the wing is covered both top and bottom with 1/32" sheet. Note

that this sheet must be glued between the ribs so it will be flush with the

airfoil outline. The center rib is cut flat on bottom so that a piece of

1/16" sheet, which fits the cabin top, may be glued flush with it. When

this piece is glued to the center rib there will be an open space between the

1/16" sheet and the 1/32" sheet on the bottom camber. Fill this in

with sheet balsa and fillet with balsa dust and dope. The wing is held in

place by rubber bands stretched from two hooks anchored to the keel near the

leading and trailing edges. Stabilizer

construction is so simple that no difficulties should be encountered. After

it is covered it is glued firmly to the rudder and braced with 1/32"

wire, shown on the front view. Note that the tab, which is soft 1/8"

sheet, is hinged with thin sheet aluminum. Propeller and Spinner Success with

any model depends largely on the propeller, therefore great attention should

be given to this. Carve the blank as show on Plate I. The approximate blade

shape can be determined by the dotted lines on the blank. The blades are about 1/8" thick half way to the tips After the prop

is finished bend the folding-prop lifting to fit the curve. These fittings

are lettered A, B and C on Plate II and correspond to the fittings shown on

the prop details on Plate I. When these parts are glued securely in place the

blade breaks should be cut. On folding props it is important to have the

blades free enough to fold, but tight enough to hold their pitch. Washers

should be soldered to the rubber-tensioner spring to keep it in place. The

bobbin also should be securely fastened to the prop shaft. When making the

hook which fits into former A, glue in the aluminum fittings (A) well so that

it will hold thrust adjustments. The spinner is

carved or turned from a block with the grain parallel to the thrust line.

Finish the outside first and then cut it in half and hollow out to about

1/8" thickness, Glue the halves together and cut the completed spinner

so that it fits tightly over the prop hub. When winding the spinner is

removed. Flying On the side

view the position of the center of grainy is shown: it must be in this

position or slightly to the rear in order to obtain the best glide. The

original ship was powered with 16 strands of 3/16" brown contest rubber.

With this motor the prop run was about 1:15 minutes. On the second model 20

strands of 3/16" brown contest rubber, 32 inches long, was used. The

motor run was slightly under the minute mark, but altitude attained was much

greater than with the first motor. When lubed and stretched five times its

length, 700 turns can be packed into the

motor. Test flights

should be made with a gradual increase in turns. The model climbs and glides

in right-hand circles. There should be a slight wash-in on the right wing and

the tab turned slightly to the right. Be sure to put in the correct amount of

right and down-thrust. If the model

stalls check center of gravity and thrust adjustments. If it dives or glides

steeply, increase the wing's angle of incidence and move the center of

gravity to the rear. Due to its stable characteristics, you should have no

trouble adjusting the model if your surfaces are set as directed. Notes The high

mounted stabilizer seemed to increase the glide and spiral stability. Retractable

landing gear should increase performance, but is not advised unless you have

a good take-off and landing spot. If retractable gear is used be sure to fix

it so that you can leave it down for test flights: it will save the covering

on the bottom of the fuselage. The fuselage

was covered with strips of tissue, grain running lengthwise. The wing was

covered with the grain running spanwise. After the dope was applied, a coat

of glass was added to keep the tissues from tightening to the point where it

pulls in stringers and causes a sag between ribs. When yon wind

to maximum, be prepared to chase cross-country. Its fine flying

qualities and appearance will make you proud of your ship. Scanned from

June1941 Model Airplane

News |