REAL indoor flying scale models are

rare birds. The scale model usually palmed off as an indoor model is heavy

enough to fly outdoors in a stiff gale.

The Heath Midwing makes a

particularly good indoor scale model as it is very simple in design and

construction. It has no fancy doodads, such as a more intricate airplane would

have, and which, when left off, would make it look incomplete. Yet, when built,

it looks very much like a real airplane.

Our model has a tissue-covered

fuselage and microfilm-covered surfaces. The film, however, is not the

ordinary kind, but is of a solid color. How to make it will be described later.

FUSELAGE

Make a full-size drawing of the

fuselage sides and build them up of 1/16" square balsa and cement the bulkheads

in place. After the cement has dried, cut away enough of bulkheads 1, 2, and 3,

and the cross braces, so that the rubber can get freely from the propeller to

the rear hook.

Carve the nose block out of very

light balsa, leaving a thin shell approximately 1/6 " all around. The

plug, which is an aid to winding and changing the rubber, should be cut out

next. After the nose block is finished, cement it to the fuselage framework and

then cement the three upper and two lower 1/20" square stringers in place.

Draw the cockpit section full size, make one out of heavy white paper, and

cement it in place. Make the rear hook as shown in the drawing, and cement it

also in place. Now cover the fuselage with superfine tissue by coating the

longerons and cross braces with banana oil or microfilm solution, and laying

the tissue over the wet surface. Make sure that there are no wrinkles in the

tissue, and then trim the excess off. Spray the tissue with water to tighten

it.

The main landing-gear struts are made

by streamlining 1/16" balsa sheet, 3/16" wide and 1-7/8" long.

The auxiliary struts are 1/32" square strips of bamboo. Cement the wire

axles in place, slip the streamlined wheels made of sheet balsa 1/4" thick

and 1-1/8" in diameter, on them, and put a dot of cement on the ends of

the axles to prevent the wheels from coming off. The fuselage is finished by

cementing the bamboo tail skid in place.

WING

The wing is single surfaced and of

light construction. On the real plane it is braced with "N" struts,

but on the original model only two struts were used. The wing, as mentioned

above, is covered with a semi-opaque-colored microfilm.

In constructing this model it is

first necessary to make a template of the ribs from stiff cardboard. Cut out

the twenty ribs by the usual procedure from 1/32" sheet balsa by slicing

along the edge of the template, and then sliding the template down 1/32",

but parallel to the first cut, and slicing again. The spars are 1/20" square

and are pinned to the full-size drawing of the wing. The tips are made by

bending 1/32" square strips of soft balsa around the cardboard template,

and should be cemented to the spars. Insert and cement the ribs, making sure to

cut a third of any excess length from the front and two thirds from the rear.

The microfilm is made by mixing well a half ounce of good colored dope and a

half ounce of microfilm solution and pouring it on the water in the usual

manner. Cover the two halves of

the wing and cement them to the fuselage in the proper place as shown on

drawing. Make struts of 1/20" square balsa and cement them in the places

indicated on the drawing so that there is 1-1/2" dihedral in the wing

under each tip. This finishes the wing.

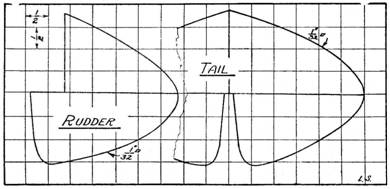

RUDDER AND TAIL

Make a full-size drawing of the tail

and rudder, and make templates of them from stiff cardboard. Bend strips of

1/32" square balsa around the templates and then pin the outlines to the

full-size drawing. Insert the auxiliary spars, cover them with microfilm, and

cement first the tail and then the rudder in place on the fuselage.

PROPELLER

The propeller is carved from a very

light block 3/4 x 1 x 7" in the usual manner. That is, first draw the

diagonals on the broad faces and remove the wood to them (allowing for a hub)

with a sharp knife. Smooth the edges and then fashion the concave sides of the

blades, using a knife at first. Progress to a razor blade and then through the

various degrees of sandpaper until the concave sides are completely finished.

The convex side should be carved with the razor till the blades are 1/16"

thick at the tip and 3/32" thick at the hub. Then use varying degrees of

sandpaper till the hub is 1/16" thick and the tips 1/32" thick. Make

a template of the blade shape of paper and cut the blades to fit. Trim and

smooth the edges and insert the shaft, first through the nose plug (and after

slipping three washers on the shaft), then through the propeller and cement it

in place. Cement one of the washers to the nose plug and one to the propeller,

making sure that no cement gets on the surfaces exposed to the rubbing.

FLYING AND ADJUSTING

Cut out the rear section of tissue

from one of the sides of the fuselage and force a loop of 1/8" flat brown

rubber through the fuselage. Connect it to the propeller shaft and put the nose

plug back in position. Glide the model. It should glide well if you have the

nose block of the proper thickness and the wing and tail set correctly. Any

necessary adjustments can be made by moving the elevators. If the model

stalls

or dives badly you will have to weight the nose or tail

accordingly. After a good glide is obtained, wind the model a few turns and

launch it. It should fly in approximately forty-foot-diameter circles. If it

does not, bend the rudder. The original model, which weighed two ounces, turned

in several flights of over two and a half minutes and appeared to be

overpowered. With 7/64" rubber the model would have probably flown nearly

four minutes, but an unfortunate argument with a large glider (in which the

glider won) ended its career.