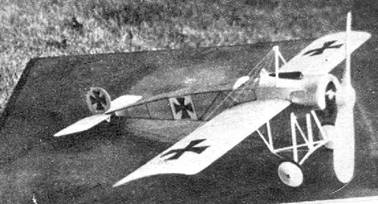

THE author used medium weight balsa

for all parts except the landing gear which is hardwood dowel. The model is

designed as closely as possible with available data to the scale of 1/2"

to the foot. The only part not to scale is of course the propeller, which

however is realistic and close to scale. Built very lightly, the author's model

weighs only 1/2 oz.

The fuselage is constructed first,

the two flat sides (shown in solid black) being laid out directly over the side

view. Study your plans carefully and note the solid 1/16" balsa side

section at front of fuselage; also note gussets at the junction point of wing,

and the small gusset at tail of fuselage to provide solid juncture point for

the elevators. All longerons, uprights and diagonals are of 1/16" sq.

balsa. Join the fuselage sides first at front and back, then add all remaining

crossbraces which are also of 1/16" sq. stock.

The fuselage of the real E-III was

square except for the three formers at front and on top of fuselage. These

formers, shown on Plate 1, are cut from 3/64" sheet stock and cemented in

place as indicated. The stringers are 1/16" by 1/32" and are cemented

in notches on formers. Now from a small block of balsa carve the two cowl

fairing pieces to outline; note the dotted lines on side view of fuselage.

Construct the motor cowl next,

cutting the two formers from 1/8" sleet stock. The front plate is clearly

shown on the front cowl former pattern by dotted lines; it is cut from

1/16" sheet stock with a small hole as indicated for the nose plug. This

front plate is cemented to the back of the front cowl former.

The cowl is formed by connecting the

two formers by 1/16" sq. Stringers placed in notches, the stringers being

only 7/16" long. This assembly is now covered with 1/64" sheet balsa.

When dry, cowl may be sanded to crossection indicated in side and top views,

and glued in place. With cowl in place and cement dried, streamline the two

side fairing pieces, using razor blade and sandpaper. (The author finds the

small fingernail emory boards used by his wife very handy for such streamlining

etc.; they can be purchased in most dime stores.) With the cockpit outline of

heavy bond paper and the tail skid in place, only the rear motor hook is

necessary to complete fuselage. This latter part is a small 1/16" diameter

hardwood dowel inserted through sides at point indicated just forward of

elevator by small black dot on side view.

The tail surfaces are next on our

production list. The rudder is simply cut from 1/32" sheet, and the

elevators are built of 1/16" flat stock of widths indicated on Plate 1.

Elevator should be built in one piece, so it is essential to complete left

half by tracing right half and reverse the tracing. Elevator is flat without

camber.

Wings are next. Note that two rib

outlines are shown on wing plan. The author used the scale rib on his model with

excellent results. However, the less experienced builder may prefer to use the

non-scale rib with camber on top surface only. The latter rib has the added

advantage of being deep enough to accommodate a 1/16" sq. spar. The

author's model with the scale rib has no spar and may be duplicated

successfully if the builder is cautious and accurate in his work. In any

event, the wings are constructed directly over the plans. The right wing plan

may be duplicated by tracing and reversing. Crossections of leading and

trailing edges are each 1/4" wide. The wing tips are of 1/16" flat stock.

Tips are easily cambered to same curve as top of the rib by soaking in hot

water and allowed to dry. The small circles on the third and fifth ribs are the

points at which the wires attach to wing. These points can be easily reinforced

by a cement coating, or the builder may wish to reinforce the sides of the ribs

with small balsa scraps.

With fuselage, tail surfaces and

wings finished, we are ready to cover; that is, after all frameworks have been

sanded smoothly with very fine sandpaper, or preferably with the fine side of

previously mentioned emory board.

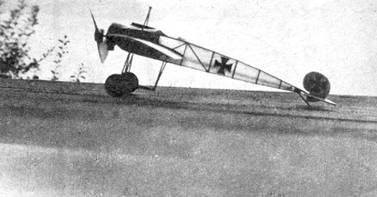

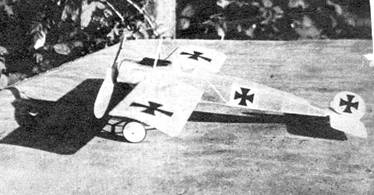

Now comes the job which can ruin the

most carefully constructed model. Caution - take your time! To make the model

as light as possible, the author used (and recommends) lightweight colored

tissue. Since most German World War I fighters were gaily colored, a pleasing

effect was gained by using bright blue tissue for the fuselage, and yellow for

the wings and elevators. Now note accompanying photographs. From the solid

sheet sides back to the second upright, use one piece of blue tissue; between

second and third uprights use a small piece of white tissue (this gives a white

background to the insignia); and from third upright to rear, use another piece

of colored tissue.

The author at this point would remind

the builder that when covering all parts it is desirable to cover with the

tissue grain running the longest way. The curved portion of the fuselage bottom

just forward of landing gear is best covered with bond paper; aft of this, use

one piece of blue tissue. The small turtle deck just aft of cockpit is covered

with one piece, while the entire flat back portion of top is covered with

another single piece. Forward of cockpit, several small pieces can be used to

secure a smooth job. The front portion of fuselage is later color doped.

Now cover elevators, using one piece

of yellow tissue on each side. Trim first side covered with razor blade so that

no tissue extends beyond edges. A margin of 1/8" all around elevators

should remain after other side is covered. With care, all exposed wood portions

can be covered by utilizing this margin.

Rudder, being solid 1/32" sheet,

is not covered; it is instead given a light sanding, and a small bit of clear

dope is rubbed with index finger into each side. This gives a smooth light

background for applying insignia.

Wings are carefully covered, one

piece to each side. If scale ribs are used it will be necessary to put tissue

cement on bottom of each rib so the tissue will adhere to the concave surface -

otherwise spread tissue cement (or clear dope, which author prefers to use)

only on outline of surface being covered.

With covering completed, spray all

parts with an atomizer taking care that the wings do not warp. Clear dope is

used on fuselage only! Do not dope wings and elevators; to do so will cause the

light framework to warp.

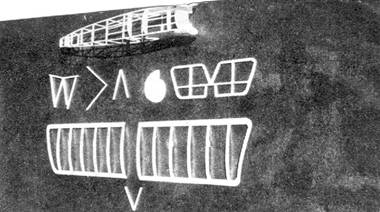

Now for the landing gear which is

made of 1/8" by 1/16" hardwood strips sanded to streamline shape.

Check accompanying photo of framework, then construct directly over plan on

Plate 2 the front vertical member of the landing gear. This front framework

consists of struts A, A, B, B, and C. When dry remove from board and construct

the rear vertical member which is merely a "V" of struts A, A. The bottom,

or horizontal assembly, is made in like manner directly over plan on Plate 2.

When these members are thoroughly dry cement them in place, using plenty of

cement and being careful to observe from side view, Plate 1, that the rear

"V" member slants forward very slightly. When attaching front and

rear struts it is best to remove tissue very carefully from framework at point

of attachment. Checking front view, install small music wire axles in proper

place; bind same with thread and cement firmly.

Now install the cabane strut

(inverted "V") just forward of cockpit in same manner as landing

gear. It is built over front view plan and is cemented in place at this time.

Note the small rectangular block at top of cabane strut; this is made of scrap

balsa and is cemented securely in place.

Wheels are made lightly in following

manner: on 1/8" sheet stock, using a compass, draw an outside circle

1-1/8" diameter, and inside circle 7/8" diameter. Cut out inside

circle first, then very carefully the outside. Wheel disks are made by cutting

from bond paper, four disks 1-1/16" diameter. Noting Plate 2, you will see

that the wheel disks are slit and overlapped 1/8". This makes a shallow

cone for each side, light yet sufficiently strong for this little plane. A

simple but effective bearing is made at center of, each disk by making a small

spot of cement. Wheels are held in place on axle by a drop of solder, or

another drop of cement.

Now for assembly. Cement elevator in

place with no incidence, then rudder. Wings are cemented in place without

dihedral and with 5° positive incidence.

The front portion of fuselage,

noting, photos, the motor cowl, landing gear and tail skid can at this time be

color doped silver. Windshield is cut from celluloid according to front view;

machine guns are made from balsa scraps, doped black and cemented in place just

in front of cockpit.

A suggested dummy motor for the flying

scale builder is shown on Plate 2 at top of same, and for the detail addict a

complete dummy motor of nine cylinders may be placed inside the cowl of a nonflying

model. The dummy partial motor is cemented to the sides of the cowl. Dummy

motor and front cowl plate, of course, are doped black.

Refer to photos and add landing and

flying wires; a small additional stress wire is added (as shown on front view)

between wing leading edge and point 1/4" to rear of cowl front. Add

Maltese Cross insignia of black tissue.

Carve propeller from balsa block of

size noted on plans, add prop shaft of medium music wire, install same with

nose plug, washers, two loops of 1/8" flat rubber well lubricated and your

E-III is ready for test flight.

Test first by gliding into tall

grass. Small weights can be placed in back of dummy motor or under elevators

for balancing.

The author's E-III flew with no

balance weights, but materials etc. cause various models of the same plane to

have different characteristics.

The original plane used wing warping;

hence no aileron outlines are needed. Likewise, the entire elevator and rudder

assembly was hinged.

The enterprising builder can add

details from magazine photos. Take your time, work carefully, and you'll have a

very unusual model of which you can justly be proud.