Fundamentals of Model Airplane Building A Complete Course for Beginners By EDWIN T. HAMILTON HERE is the sixth model of this

series. Mr. Grant has designed, built and tested it with two major considerations

in mind, The first of these is to bring the reader additional building steps,

as has been done with the preceding five. In this progressive manner, the

reader will gradually master all construction details and operations in the

building of model airplanes. The second consideration is to give

the reader as fine a model as possible. In this all-balsa, R.O.G.

(rise-off-ground) tractor, Mr. Grant has produced one guaranteed to out-fly

any others so far designed in this particular class. How well he has

accomplished his task will become evident to all who build and fly the model

presented here. On actual flight tests, its

behavior was remarkable. With its motor only two-thirds wound by hand, it

rose to an altitude of some two hundred feet and covered a distance of eight

hundred feet. Without the aid of air currents, but wound with a winder, it is

capable of a flight distance of over twelve hundred feet and a total duration

of from ninety to one hundred seconds! Given a slight up-draft, it will

fly in. definitely to give a performance similar to the finest of outdoor

contest models. Its large stabilizer; long stabilizer moment arm, and the

combination of dihedral, sweep-back and low center of gravity, gives to this

model a stability second to none. Rising from the ground in a beautiful

sweep, it will quickly adjust itself to existing air conditions, although it

is not advisable to fly it in extremely rough and windy weather, as it weighs

only 1-1/8 oz. So let's get busy and build this

latest creation of a designer who is not afraid to guarantee his product to

beginners and experts alike. Motor Stick The motor stick is shaped from a stick

of medium hard or hard balsa wood. It should measure 3/16" thick, 3/8"

wide and 18" long after being cut and sandpapered smooth. As will be

seen in the plans under "Top View," it retains its original thickness

along its entire length, but its width varies from 3/8" to 3/16". This is shown in the plans under "Side View," Note that this variation in width

is obtained by shaping the upper edge of the stick only, while the bottom

edge remains perfectly straight. It is in the form of a taper and is now

ready for laying out. Choose either end as the front or leading end of the stick and so

mark. From this end, measure a distance of 7" along the stick. From this

point, the stick is tapered from its original width of 3/8" to a width

of only 3/16" at the front end. Cut this taper and sandpaper smooth, A distance of 8" is now

measured from the rear or trailing end of the stick. From this point the

stick tapers from its original width of 3/8" to a width of 3/16" at

the trailing end, The remaining 3" between these front and rear tapers

remains 3/8" wide. Cut this second taper and sand smooth. The upper front edge of the stick

is now rounded, as shown in the plans under "Side View." Tail Boom The tail boom is of the same

grade of balsa wood and when sandpapered smooth, should measure 1/8"

thick, 3/16" wide and 6" long. Choose either end as the front and

so mark. From the front end, the boom retains its original 1/8"

thickness for a distance of 2-5/8". Lay this out and mark. From this

point to the rear end of the boom, the thickness is tapered from 1/8" to

1/16". Note that this taper is cut on one edge only, which becomes the

bottom edge, while the other edge which becomes the top edge of the boom,

remains perfectly straight. Cut this taper and sandpaper smooth. The upper

front edge of the boom is now rounded, as shown in the plans. Two small balsa blocks measuring 1/8"

x 1/8" x 3/4" long are now cut and cemented on both sides of the

boom 2-1/4" from its front end, as shown in the plans under "Top

View." These are to add strength to the boom at its weakest point, as

well as to steady the elevator. Shape their bottom edges to match the taper

of the boom. The boom is attached to the stick

at its rear end with cement reinforced with thread binding. Note that its

3/16" width continues the 3/16" thickness of the motor stick. Care

must be taken to cut away the top edge of the motor stick, so that when the

boom is attached in place, its straight top edge will be parallel with the straight

bottom edge of the motor stick. At the same time, the sides of the boom must

be in a straight continued line with those of the stick. The front end of the

boom overlaps the rear end of the stick l" as shown in the plans under

"Top View." Cut the top of the stick as

required. Before the boom is attached, however, the combination rear hook and

tail skid must be bent, as these three parts - the stick, boom and this metal

fitting are all cemented and bound together. The combination rear hook and

tail skid is bent from No. 13 piano wire. As it is shown in the plans full

size, it should be bent to match the one given at the top of the plan

perfectly. Cut a small groove along the top-center of the boom slot in the

motor stick, so that the top bend of the skid will fit into it perfectly.

When in place, coat the slot with cement and place the boom in position on

the stick. Now coat both the stick and the boom with cement and then wrap

with thread until all three parts are held tightly. When completed, the

thread may be given an outside coat of cement to further strengthen it. Elevator The elevator is cut from a piece

of 1/32" sheet balsa measuring 3" wide and 11" long. Note the

elevator shown in graph at the bottom of the plan. Rule paper with 1/4"

squares, copy the elevator, fullsize on this paper, trace it on the balsa

sheet and cut out. Slightly round and smooth all edges and then carefully

sandpaper the piece until slightly thinner than its original thickness. Rudder The rudder is cut from a piece of 1/32" sheet balsa

measuring 3" wide and 4-1/4" long. It is shown in graph at the

bottom of the plan, Proceed to cut this piece in the same manner as was the

elevator. Finish with sandpaper in the same manner. As the rudder is

cemented to the elevator, it may be assembled at this time. Two sheet balsa strips are added

to the sides of the rudder to increase the thickness of its edge for

cementing purposes. These are shown in the plans under "Side View."

Each should be cut to measure 1/32" x 3/16" x 3" long.

Sandpaper them smooth and then cement them on each side of the rudder along

its straight bottom edge. This assembly is then cemented to

the center of the elevator, as shown in the plans. The trailing edge of the

rudder must be flush with that of the elevator, the rudder must bisect the

elevator, and the trailing edge of the elevator must form right angles with

the rudder. Wing

Study the plan of the wing. Note

that it is cut from two, pieces of 1/32" sheet balsa measuring 4' wide

and 13-5/16" long. Cut these two pieces to exact size. Note that one of

them is shown on the left side of the wing in the plans by dotted lines.

Measure 2" in from one edge and then draw a line along the center of the

wing board bisecting it. All measurements are laid out on each side of this

line. At the tip of the piece, measure 1" on each side of the line, Lay

out the trailing edge of the wing by drawing a line from the trailing end of

the inner end of the board to this 1" point. Draw a second line across the

width of the board at right angles to the trailing edge line so that its

forward end meets the inner front corner of the board. This line forms the

inner edge of one wing half. From the leading end of this

inner edge, measure 1/2" along the leading edge of the board. Now draw a

line from this point to the 1" point at the wing tip. This forms the

leading edge of the wing, Make a graph of the wing tip, trace it on the board

and cut out the wing half. The second wing half is cut out in the same manner.

Finish smooth with sandpaper. Both halves should now be tested

to see that when placed together they form a perfectly straight trailing

edge. If not, their inner edges must he sanded until a perfect fit is

obtained. At the same time, the entire wing span must measure exactly

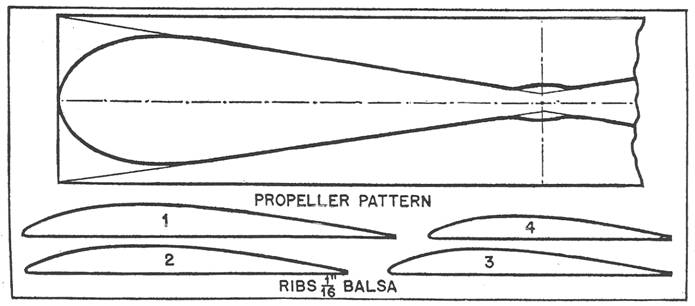

26". Each wing half requires four wing

ribs, which are shown full-size in the accompanying drawing. Trace these on

thin paper, transfer two of each rib on 1/16" sheet balsa and cut out.

Finish carefully with sandpaper. Assemble the ribs on each wing

half before joining the halves together. Note their positions as shown in

the plan under "Wing." Rib No. 1 which is the largest, is placed 1/2"

in from the inner edge and parallel to it. Rib No. 2, the second largest, is

placed 3-1/4" in from the inner edge or 2-3/4" in from rib No, 1.

The third rib is placed 2-7/8" from rib No. 2, while the smallest and

last rib, (No. 4), is cemented 3-7/8" from the wing tip or 3" from

rib No. 3. Apply cement to both the ribs and

the underside of the wing half and carefully bend the wing around the ribs.

Hold with pins until dry. The second half is assembled in the same manner. Balsa sheeting, measuring

1/32" thick and 5/16" wide, is cemented between ribs No. 1 and No.

2 on the leading and trailing undersides of each wing half for added

strength. The inner edges of each wing are now beveled to match each other

perfectly when the wing is given a 2-1/8" dihedral at each tip. Obtain this dihedral in the usual

manner and then cement the halves together. Two additional balsa sheetings

are now added along the underside of the wing at the leading and trailing

edges between the No. 1 ribs of each half. Like the others, these must

measure 1/32" thick and 5/16" wide. They must be cut 1" long,

bent to fit the dihedral angle and cemented.

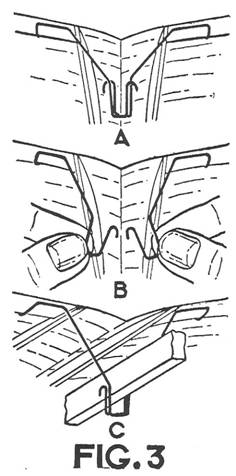

Mr. Grant has developed a new

type of wing clip for this model. It consists of four pieces of wire, two of

them forming the leading edge clip and two the trailing edge clip. Note their

full-size form at the top of the plan. They are bent from No. 6 piano wire.

Bend two front clips and two rear clips. Instead of going directly into the

wing structure, these clips have a bent lip on them which extends inward on

the underside of the wing before they are bent up to enter its wood surface.

These bends are shown at "A" and "B". The former is for

the leading clips, while "B" is for the trailing ones. These clips come up to the edge

of the wing, extend along the edge, turn in at right angles, extend toward

the center of the wing and are then bent up and inserted into it. Note this

in the illustration showing the clip on the wing, marked Fig. 3. Test your

bends to see that the trailing clips are exactly 1/8" shorter than the

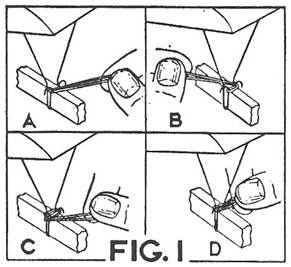

leading clips. The wing is attached to the motor

stick by spreading the hooks of each clip apart, passing them over the stick

and bringing them together under it, where they are held together with short 1/2-inch

long rubber bands. The attaching of these bands is shown in Fig. 1. Propeller

The propeller is carved from a

medium hard balsa block measuring 7/8" thick, 1-3/4" wide and

10" long. Lay out the pattern as shown full size in the drawing, and

then carve in the usual manner. Its hub is cut away on the inner side or on

the side from which the propeller shaft protrudes. Bend a propeller shaft from No.

13 piano wire to the exact size shown in the plans. Insert it through the hub

from the inner side, bend it around as shown, pull it back so that the end

enters the hub wood and acid cement for strength. Landing Gear The landing gear is bent from a

single piece of No. 13 piano wire, as shown in the plans, Note that this

piece extends up to the stick, goes forward along its bottom edges and then

forms a bend around the motor stick. In this way, it must be placed over the

motor stick from the stick's upper side, as shown in the small drawing of it.

However, before it is attached to the stick, wheels must be cut and the

propeller bearing must be bent. The wheels may be of hard wood

and if this is used, they may be 1-1/4" in diameter and 3/16"

thick. If balsa wood is used, they should be 1-1/2" in diameter and 1/4"

thick. Cut these out, sand to perfect circles and attach to the landing gear. A regulation propeller bearing is

cemented to the underside of the motor stick. Slip the landing gear over the

stick, apply cement and then bind both the gear and the hearing with thread.

Apply a coat of cement over the finished binding for added strength. Note

that the landing gear wire at the lower end extends back a distance of 1-3/47". Motor Power The motor consists of six strands

of black or brown rubber and is attached to the combination rear hook and

tail skid by a second hook, known as an "S" hook because of its

shape. Note this at the top of the plan. It is also bent from No. 13 piano

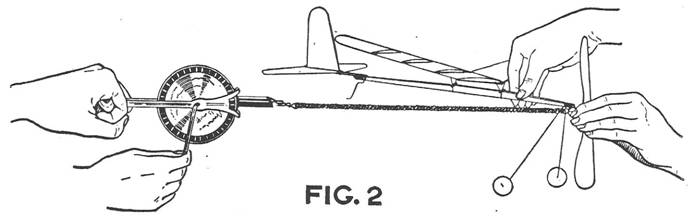

wire. Such a hook permits the motor to be wound with a hand winder, such as

is shown in Fig. 2. Tie the length of rubber together

into one loop and then pass it between the "S" hook at one end and

the propeller shaft at the other. For proper sag in the motor, a length of

100" should be used. If you wish more power, another strand may be added making

seven in all. In this case, one end is tied to the propeller shaft hook,

wound hack and forth between this hook and the "S" hook, and then

the free end tied to the "S" hook. Flying

For all strong motors a winder

should be used. These may be purchased at any model airplane supply store and

are used as shown in Fig. 2. While one holds the propeller shaft away from

the bearing, the other attaches the hook of the winder over the "S"

hook, stretches the rubber motor about four or five times the length of one

strand and begins to wind, While the winding proceeds, the one doing the

winding should slowly walk toward the model. With such a winder, this motor

can be given about 550 to 600 turns when a lubricant is used. Such

lubricants can be purchased, applied before winding and then carefully

washed off before the model is stored away between flights. If the winder is not used, a

hand-winding can he given the motor of about 300 turns. Through the balance

method, locate the center of gravity, as shown on the plan by "C.

G." in the side view. The location of the wing is determined from this

point of gravity. Note that the leading edge of the wing is set exactly 1-3/4"

in front of this point. Set the wing at this position,

wind the motor and launch the plane on its maiden voyage! Scanned

From October, 1934 Universal

Model Airplane News |